Infrastructure equipment such as data concentrators and broadband backhaul routers represent a large portion of the cost of electric utilities’ advanced metering infrastructure (AMI) networks. Reducing the required capex by optimizing infrastructure deployments helps improve overall project’s return on investment.

Utilities deploying AMI networks with power line communications (PLC) need to determine the optimal location for data concentrators to maximize the number of reachable endpoints. Today’s PLC data concentrators are designed to support up to 2,000 endpoints reliably. But are they cost-effective when geography and the design of the distribution grid result in many feeder lines with a much smaller number of endpoints?

In order to support over a thousand endpoints in a single head-end system, PLC data concentrators typically use high-performance microprocessors rather than inexpensive microcontrollers. These MPUs have the capability to address large amounts of memory to hold routing tables and data from every endpoint on the network. They also usually execute a high-level operating system such as Linux, with its own requirements for large memory. An MCU-based concentrator that only supports a small network can eliminate the costly external memory and other supporting components required by an MPU and make system design much simpler.

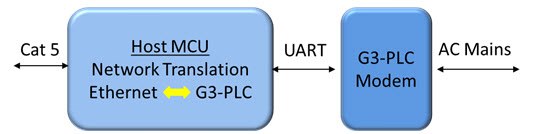

A simpler, less-complex product should also provide easy connectivity to a utility’s backbone network to allow central control of the downstream endpoints. Think of it as a form of cloud computing where the network intelligence is centralized. Figure 1 shows a simplified functional diagram of such a system.

Figure 1: G3-PLC data concentrator with Ethernet repeater

A mini data concentrator acts as an Ethernet repeater by wrapping the G3-PLC data into Ethernet packets and transmitting them across a wired network back to a central office or to a full-scale data concentrator for processing. Downstream messages get translated from Ethernet packets into G3-PLC messages. By removing this processing requirement from the mini data concentrator, you’re lowering the overall cost of the network infrastructure.

TI has just released a reference design with these factors in mind. The Data Concentrator Reference Design for Smaller AMI Networks Reduces Infrastructure Cost implements a lightweight PLC data concentrator solution integrated with the Ethernet repeater feature.

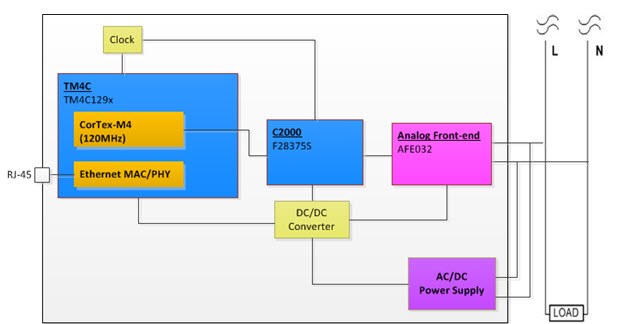

Figure 2 shows the hardware block diagram. The key components for this design are the TM4C1294 ARM Cortex-M4F MCU with integrated Ethernet MAC/PHY, the TMS320F28375S PLC MCU, the AFE032 analog front end and an AC/DC power supply.

Figure 2: TIDM-MINI-DC hardware block diagram

The TM4C1294 acts as the master MCU in the system, managing the data flow between the Ethernet and G3-PLC networks. The F28375S+AFE032 chipset provides G3-PLC connectivity for either the CENELEC-A or FCC frequency bands, as well as support for up to 32 end nodes without using any external memory.

The AC/DC offline power supply is a simple nonisolated flyback converter built around the UCC28722 controller, as demonstrated in the Snubberless, Non-Isolated AC/DC Flyback Converter Reference Design with Simplified Transformer.

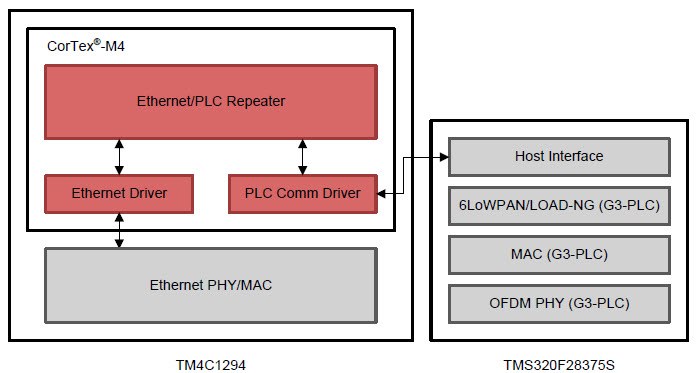

The software architecture for the mini data concentrator (Figure 3) is also simple to adopt and build upon. The G3-PLC firmware is fully resident in the F28375S and has already achieved platform certification from the G3-PLC Alliance. The TM4C1294 runs the host-level PLC communication driver and the Cortex-M4 configures the G3-PLC stacks as a mini data concentrator. The Ethernet and PLC repeater application is running on top of the Ethernet and PLC communication drivers, and its primary task is to interconnect the two networks by forwarding incoming frames from one network to the other after converting the incoming frame format. More details on the software architecture can be found on the data concentrator reference design page.

Figure 3: TIDM-MINI-DC software architecture

By simplifying the hardware and software architecture of a G3-PLC data concentrator and merging it with wired LAN access, the data concentrator reference design offers a lower-cost solution for smart grid connectivity to rural areas and low-density feeder networks. Where do you think a system like this could be deployed?