Expanding on TI’s leadership in smart metering technology, we’ve recently released a series of FRAM-based microcontrollers that enhance the operational efficiency of utility flow meters systems for gas, water and heat metering. The MSP430FR69x microcontrollers enable ultra-low-power consumption of 100uA/MHz in active mode current, and 450 nA in standby mode, all with the real-time clock enabled. This family of FR69x MCUs comes with the new extended scan interface, or ESI, and can drive up to 320 LCD segments. Combined with the ultra-low-power feature, the ESI makes this product the best fit for flow meter applications such as water, gas and heat meters with a rotor disc to detect the flow rate. These devices also come with a host of other integrated peripherals, including analog modules like a 12-bit differential ADC with an integrated window comparator and security modules like a 256-bit AES hardware accelerator.

TI’s Smart Grid & Energy application team has built a complete water meter reference design using the MSP430FR6989 MCU. This reference design equips water, gas and heat meter manufacturers with a comprehensive hardware and software solution to develop proof-of-concept demonstration and to accelerate production projects.

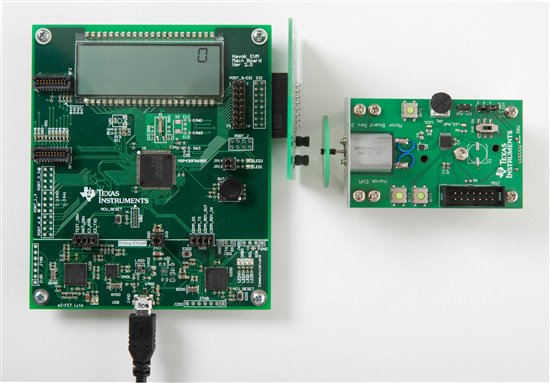

This solution consists of three boards. The main board of the EVM is built on the MSP430FR6989 MCU along with an LCD display. A battery socket is on the back of the board to provide 3V. This board includes LED status indicators, JTAG debugger and USB HID interface, through-hole connections to I/Os for debug and testing purposes. This board also houses an RF socket to support sub-1GHz and 2.4GHz communication interfaces and another socket to plug in the sensor board to the ESI interface on the MCU. This board also houses a USB interface for a user friendly GUI-based easy scan interface configuration.

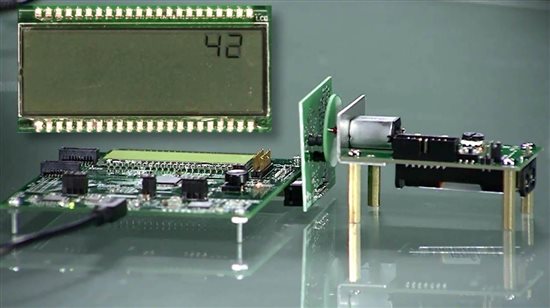

The sensor board is designed for various sensors: two LC, three LC, GMR, or optical sensors. On this board the left part of the board has been populated with LC sensors. There is a provision for populating GMR or optical sensors on the right side.

The third board in this setup is the motor board. The motor board is designed to drive the rotor disc to simulate water or gas flow. There is a battery socket on the back of the board to provide 3V. A variable resistor on this board allows for varying the speed on the disk and push buttons allows for controlling the start-stop and direction of the rotation disk.

The motor board has been setup to emulate the flow. The disk on the motor board is half metal and half non-metal. The LC sensors on the sensor board can detect both the direction and speed of the disk. Two LC sensors are used for the detection of both clockwise and anti-clockwise rotation. For more details on this tool please visit this TI design. This complete reference design will soon be available for purchase on the TI e-store.

The MSP430FR69x series of MCUs is a great fit for flow meters in the smart grid market for water, gas and heat because they include the ESI interface that enables rotary smart meters, they support up to 320 segments LCD display and because they are the newest devices in TI’s ultra-low-power family of MSP430 FRAM devices with scalable memories.

For more details on our system solutions for the global smart energy grid, be sure to check out ti.com/smartgrid and ti.com/flow