Other Parts Discussed in Thread: STRIKE

Hi Ti experts,

We now use INA146 for Battery voltage measurement when the battery is charged during the battery formation process.

Problem: There will be a ESD phenomenon of up to 500V(sometimes 1kV) between the positive side of battery and the GND of 220V input.

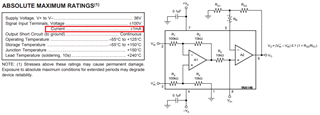

Question: So what the maximum voltage can the input side of INA146.

Do you have relevant test verification data?

What should we do to protect INA146 from ESD? It that work to connect the TVS device in parallel with the input of INA146 to ground.