Hi Sir,

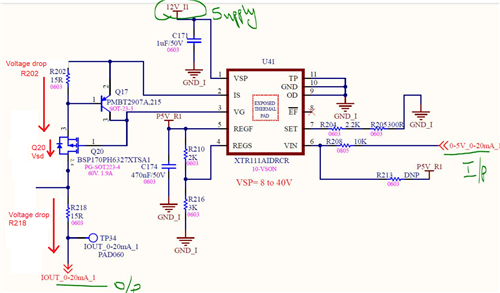

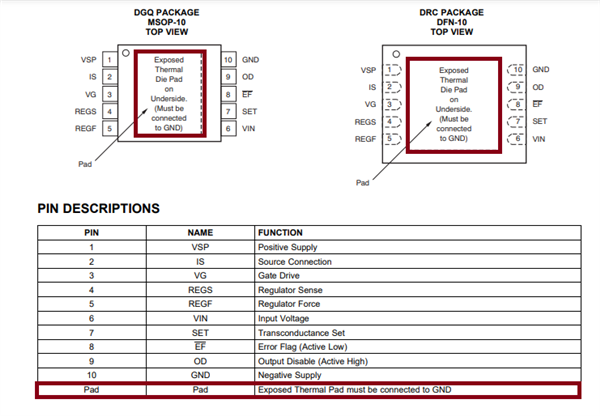

We are using the attached design for generating the 0-20mA from 0-5V input with Vsp-12V.

We got the results as per the calculation Iout-10*(Vin/Rset). For 0V- 0mA & 5V-20mA

But after 2 or 3 iterations the results are changed to

For 0V- 2.6mA and 5V-25mA.