Dear Sir,

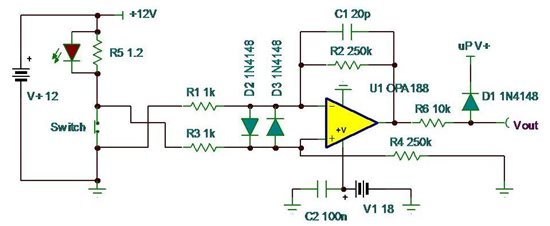

I am trying to find difference between two voltage sources using op amp. My application goal differentiate the voltage and give to ADC controller and it says what is the difference between two voltage.

I read using op amp as differentiators we can do it. but i need to get difference even it is 2 mV.

I am planning to use single supply for OP-Amp like LM324.

can i get such accurate result using op amp??

Or what else method will be good for this kind of application...

i am not good in op amp design kindly suggest a good design.

regards,

Nikhil