Hi E2E team,

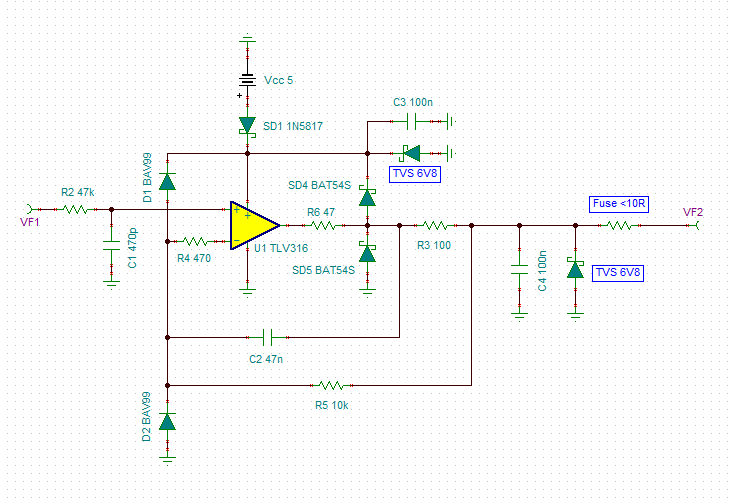

I use a TLV316 as a follower for the output stage of my sensor.

The sensor output can be analog 0-5V or PWM 0-5V 500Hz.

The ouput load (after the TLV316) can be a pull-up or un pull-down between 2k and 100k ohms.

In factory, the sensor is calibrated without load. When the device is installed in the final equipment, the calibration must not derive from these limits :

- VIN=0.5 or 4.5V - deltaV max = +/- 25mV

- VIN=2.5V - deltaV max = +/- 18mV

TLV316 is powered in 0-5V.

For now, I'm getting these results:

These values are the result of : (Vout with Pu or Pd) - (Vout with no load)

| Pu 2k | Pd 2k | Pu 4k7 | Pd 4k7 | Pu 10k | Pd 10k | Pu 47k | Pd 47k | Pu 100k | Pd 100k | |

| diff / noPull | diff / noPull | diff / noPull | diff / noPull | diff / noPull | diff / noPull | diff / noPull | diff / noPull | diff / noPull | diff / noPull | |

| 4,5V | 0,009 | -0,064 | 0,004 | -0,027 | 0,003 | -0,014 | 0,002 | -0,002 | 0,002 | 0,000 |

| 2,5V | 0,038 | -0,034 | 0,008 | -0,005 | 0,009 | -0,006 | 0,002 | -0,001 | 0,002 | 0,002 |

| 0,5V | 0,064 | -0,009 | 0,028 | -0,001 | 0,013 | -0,002 | 0,001 | -0,002 | 0,000 | -0,001 |

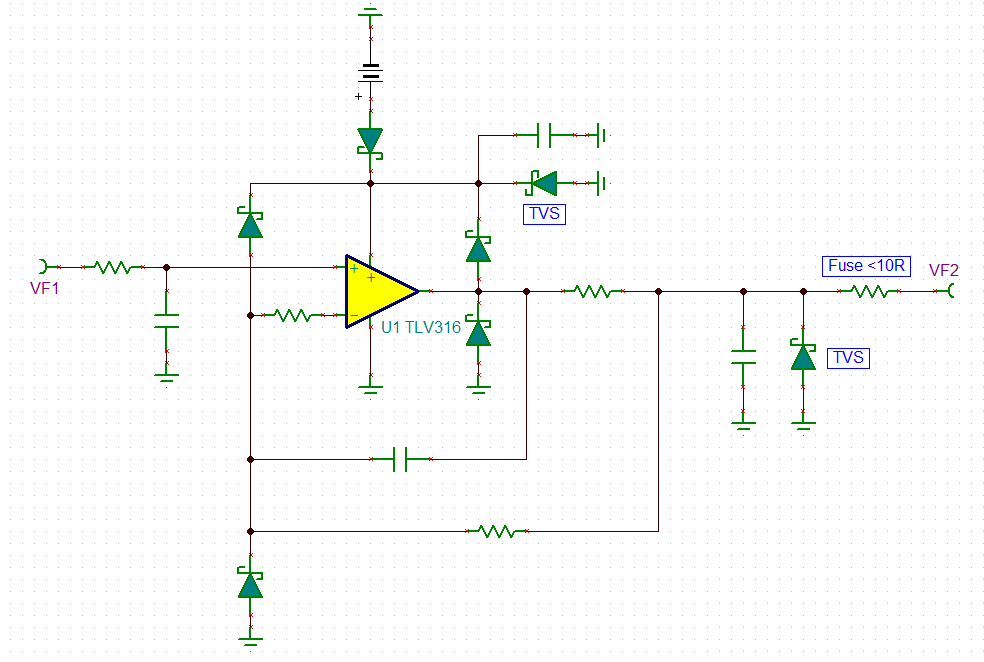

with this schematic :

Can you propose me a solution which can be compliant with my requirements ?

Thank you for your help,

Best regards,

Bertrand.