Hi,

We use INA250A4PWR in our products. When testing products, we noticed that we read different output values for the same load and supply values. We tested 20 pieces. Most of them(15 pieces) gives 4,16V output, but 5 of them gives 3,66 V output. in the technical document I could not see that this was something ordinary and I wanted to ask.

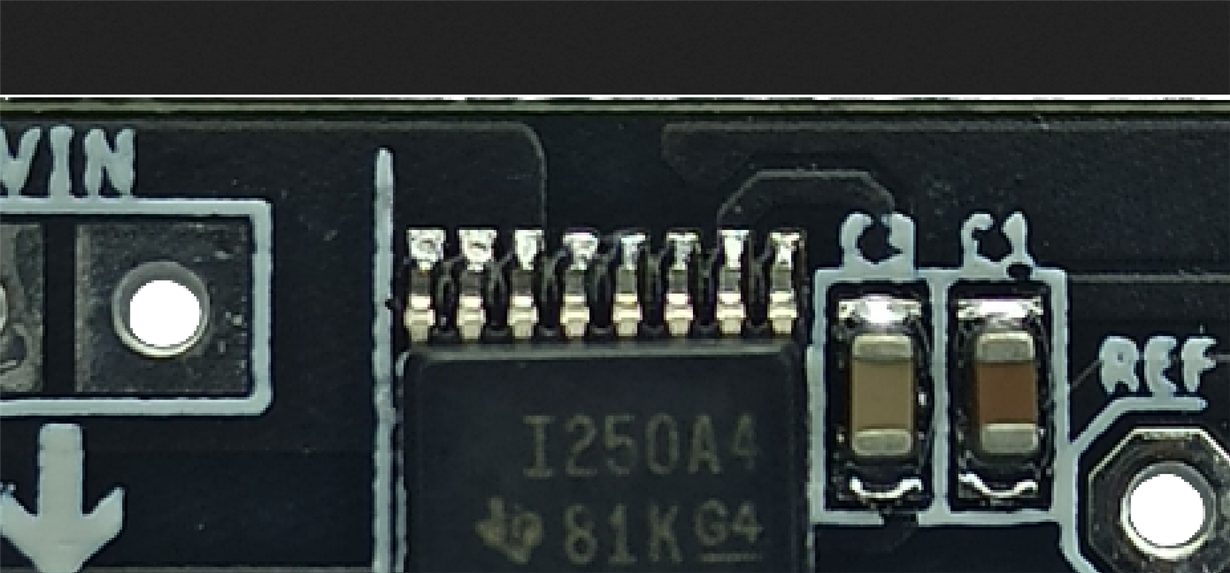

in the diagram below, we used adjustable regulator for supply. None of the tested products change the output voltage by changing the supply voltage as expected.

Best Regards

Harun