Other Parts Discussed in Thread: , MULTI-CAL-SYSTEM

Hi there,

I asked a question a few weeks ago regarding the PGA309 calibration spreadsheet for the obsolete version of PGA309EVM software. It's been closed but I wanted to follow up on it as I still haven't determined the best path forward.

https://e2e.ti.com/support/amplifiers/f/14/t/943207

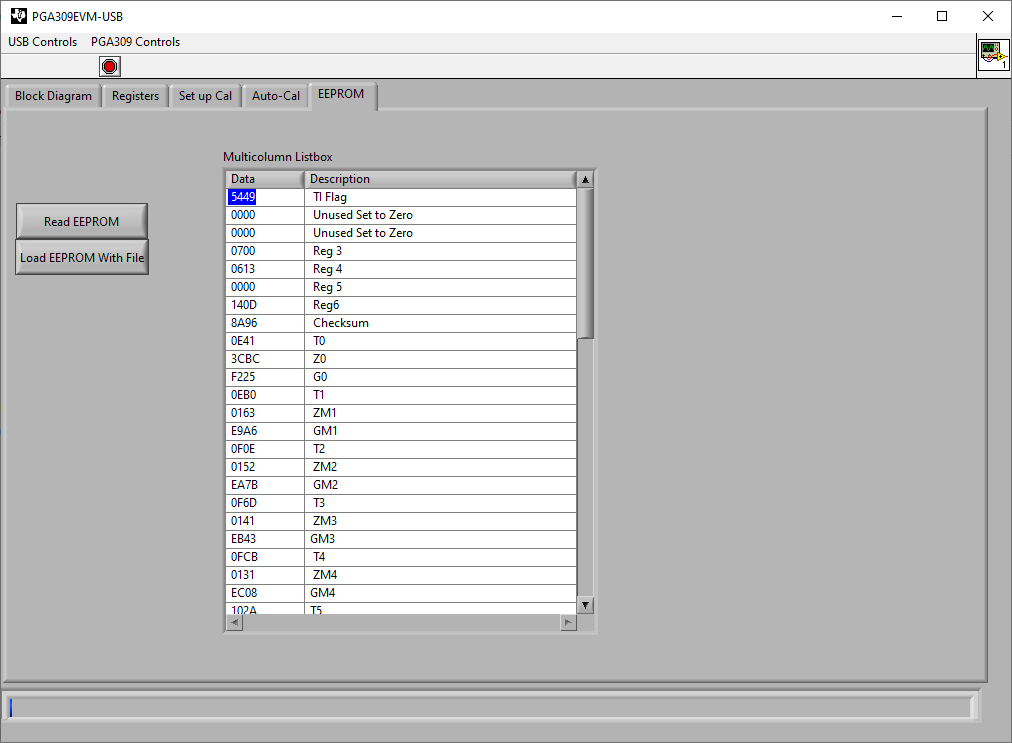

Our current process is to mate the physical pressure sensor with the PGA309 electronics (and serial 4k EEPROM), collect pressure and temperature excursion data from the sensor, and do some conversions with the old spreadsheet provided to program the EEPROM through the PGA309EVM software (old version, referenced in previous question).

We want to move to the newer version of the software. If I am collecting pressure and temp data, would it make sense to type (preferably script?) that data to the input fields of the "calibration info" of the "Auto-Cal" tab, and use that to program the PGA309? I guess my confusion is that we take data by our own means, and I'm unsure of the best way to calibrate from here.

Any help would be appreciated!

Thank you

Torin