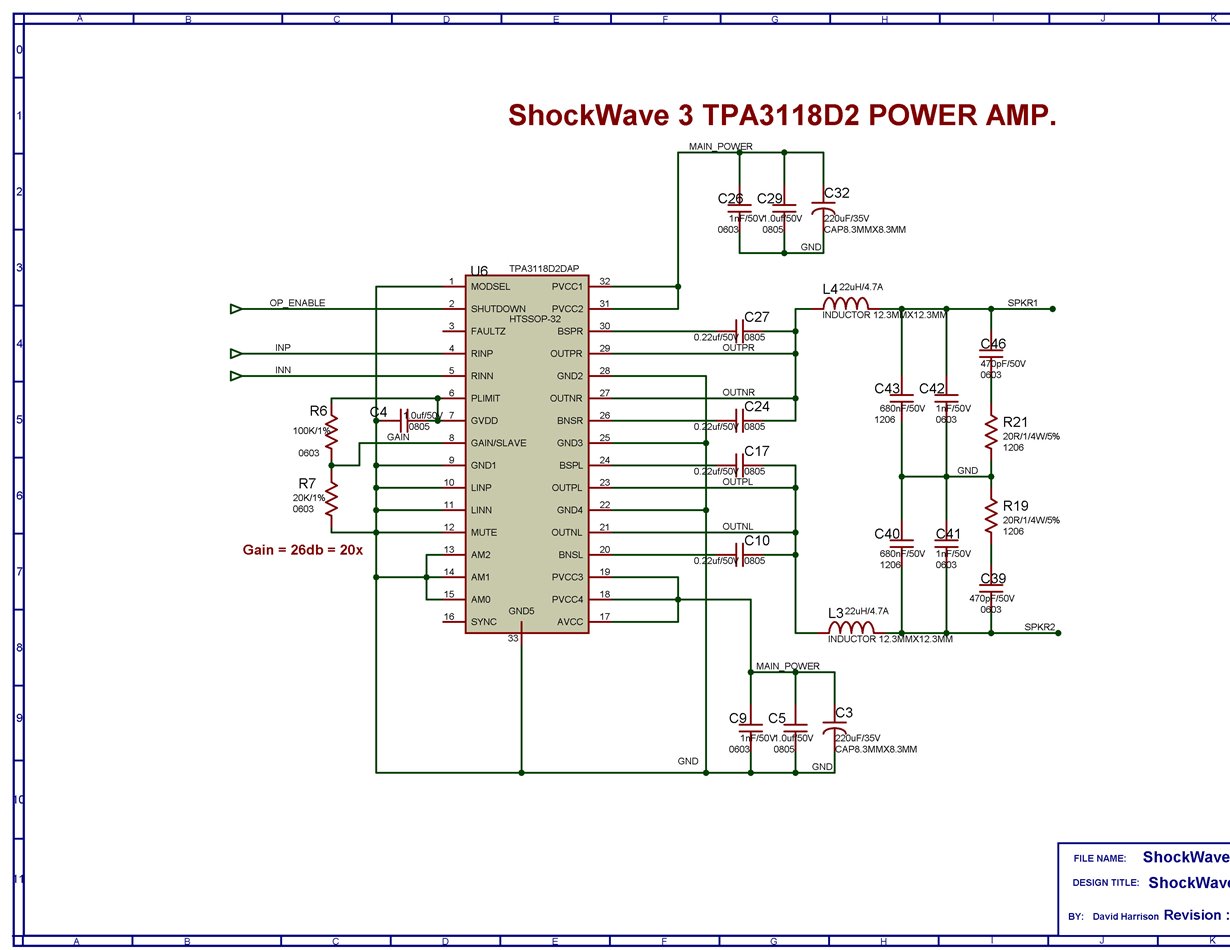

Hi, over the last 5 years or so, I have had manufactured for me about 1000 boards in different batches using TI part TPA3118D2DAP. Consistently, batch after batch of 105 pieces, about 5% have to be rejected due to a non functional TPA3118D2DAP part. The parts have power, are enabled and have an input signal, but provide no output signal. The last batch we made (in our ISO 9002 certified assembly plant) had a reject rate of about 20%! After paying extra money to have those chips reworked and replaced, the products worked correctly.

We have always purchased these parts from reputable North American suppliers such as Digi-Key and Mouser.com.

Why is such a high percentage of bad chips getting through TI's testing and the supply chain to its distributors?

On another note, I see that a newer part - TPA3118D2-Q1 is now available. What is the difference between the older part and the newer one?

Thanks.