Other Parts Discussed in Thread: OPA2188, ADS8688

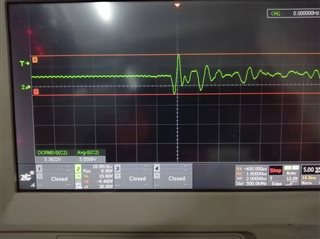

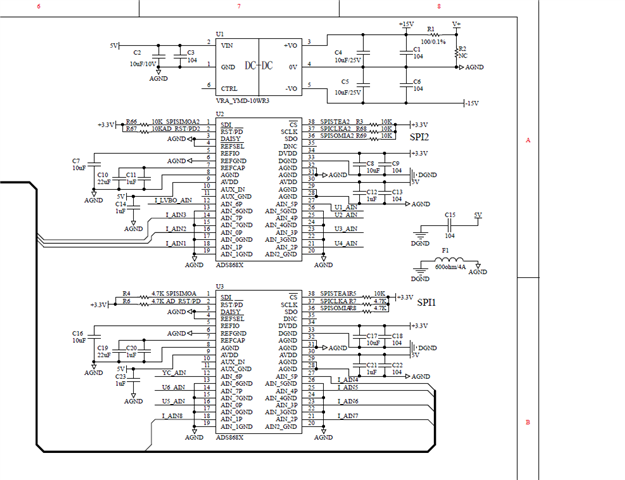

ADS8688A was used in a power source device. when power up, some switches opened/closed, 8688 got malfuction sometimes. three phenomenon

1、ref voltage changed to 3.7V from 4.096V or the voltage is drifting

2、all sample data is 0xFFFF or 0x0000

3、chip may get hot

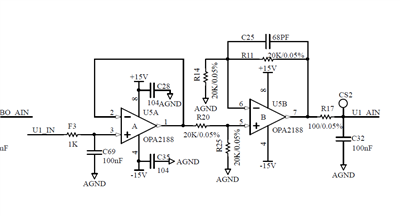

the circuit is as follow,

how can i solve this, i have tried to add diode to U1_in and tvs to u1_ain, it did not work