Other Parts Discussed in Thread: OPA2350, , THS4521, OPA350, REF5020

Hello E2E Experts,

Good day.

This thread has been locked.

If you have a related question, please click the "Ask a related question" button in the top right corner. The newly created question will be automatically linked to this question.

Hello E2E Experts,

Good day.

Hello,

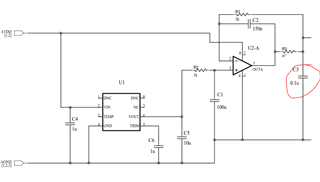

Yes, the example input amplifier circuit on page 39, Figure 89, not only drives the ADC input, but also performs as an antialiasing filter. Assuming the CLK frequency is 27MHz, it will provide better than 55dB of attenuation for any input signals in the fCLK/4 band.

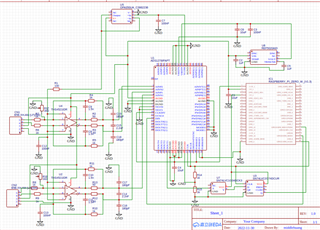

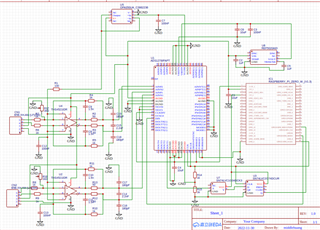

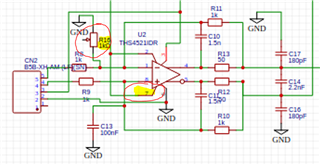

There are a few schematic errors for the input amplifier.

1. Pin 7 is the power down pin. It should either be left floating or connected to the +5V supply, pin 3.

2. Resistor R16 should not be included. This will cause an unbalanced differential signal and will not perform as expected.

3. The reference should use a buffer circuit for best performance. U2-A in below is OPA2350.

4. There are many missing pin connections on the ADC. All digital inputs need to be connected to IOVDD or GND depending on desired functionality. The external thermal pad EP, pin 65, needs to be connected to ground.

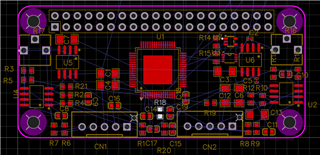

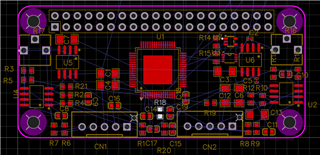

5. Regarding the layout, all power supply bypass capacitors, reference capacitor, and input capacitor should be placed as close as possible to the ADS1278 pins to provide good performance.

6. For layout, a single ground plane is recommended. All ADS1278 ground pins (AGND and DGND) as well as the thermal pad, should be connected to the same ground plane directly beneath the ADS1278 package for reliable performance.

It appears the customer is using Frame Sync. If the host processor does not support this type of interface, it can be difficult to get it to work. If the maximum data rate needed in the design is 105kSPS or lower, I suggest using SPI mode, which is supported by all processors. In the case of SPI, the CLK frequency can be set to 27MHz.

Once the customer has updated the schematic, please send updates and I will review. Also, please confirm with customer what maximum sample rate is needed in their design.

Regards,

Keith Nicholas

Precision ADC Applications

Hello Keith,

Good day.

Hello,

I will review the updated schematic by end of business this week. The changes described should work well. There should not be any problems leaving pin 7 of THS4521 floating; this pin is internally pulled high to default to power-up state.

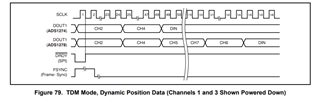

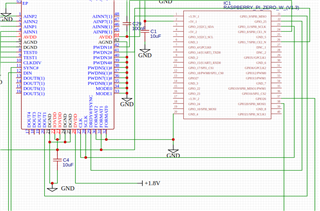

An RTOS is not required, but you should use an interrupt routine to monitor the DRDY output signal of the ADS1278. Trigger the interrupt routine on the falling edge of DRDY, and then clock the data out of the ADC as needed. You can use FORMAT=010, but you will need separate SDI inputs on your processor. Since you are operating at a low data rate, 2000sps or less, I would suggest using FORMAT=000, which will send all data on a single SDO line.

Regarding R16, the best way to accommodate different sensor output ranges is to add some additional buffers. I will provide a suggested input circuit when I review the updated schematics tomorrow.

Thanks,

Keith

Hello,

Since this is an IEPE data acquisition design with two channels, I suggest looking at the new TI Reference Design for IEPE sensors.

TIDA-010249, Four-channel synchronous vibration sensor interface reference design

Although this design supports 4 channels, it can easily be modified to support 2 channels as well. It includes a user's guide with schematics and suggested board layout.

Regards,

Keith

Hello Keith,

Good day.

Hello,

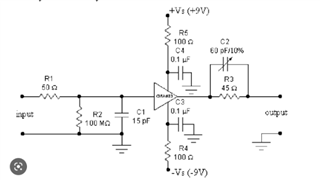

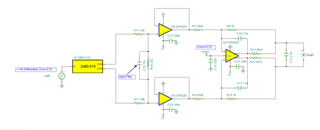

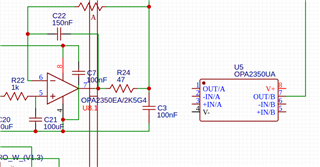

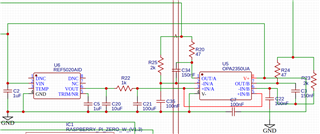

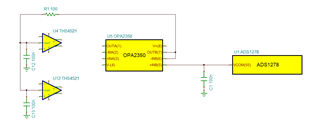

The input amplifier for the ADS1278 can convert a +/-6V single-ended input to the full scale input range of the ADS1278, which is +/-2.5V differential. Below is a circuit that can accomplish this.

If you are using the Silicon Labs sensor, the output is already differential, and produces a full scale output of +/-4V differential with a common mode of 2.5V. If using this sensor, then the below circuit will scale the output correctly.

The sensor is limited to 2kHz of bandwidth. You can add a single capacitor at the first stage amplifier input to create an additional low pass filter, which should provide more than 80dB of attenuation of any aliased signal.

Yes, for the digital communications, you must monitor the state of the DRDY pin. When this pin goes low, it indicates that the conversion result is complete and the host processor should read the data. If you processor is fast enough, you can poll this pin, or more typically, use a hardware interrupt.

When using FORMAT mode = 000, data for all channels will be output on DOUT1 pin. Please refer to Figure 79 for more details.

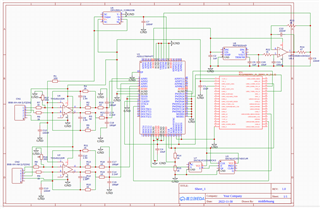

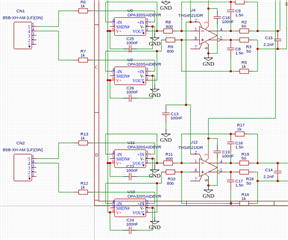

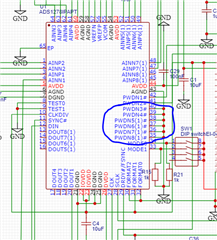

Regarding your schematic design, below are several corrections that should be made.

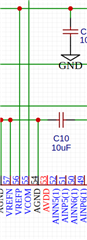

1. For the reference pins, add an additional 10uF cap directly next to the ADS1278 VREFP and VREFN pins.

2. U5 can be replaced by the additional channel in U8.1. OPA2350 is the 2 channel version of the OPA350.

3. Add a 0.1uF power supply bypass capacitor to all IC power pins, including U8 (pin 8 to pin 4), U5 (pin 7 to pin 4).

4. Add 0.1uF power supply bypass capacitors to each of the ADS1278 AVDD power pins.

5. The SYNC pin11 should be connected to an IO pin on the host processor. This pin can be used as a RESET function for the device, and should be toggled by the processor after the power supplies are stable.

6. Because you are using SPI mode, you can eliminate U7 and U3. These additional parts are only needed when operating in the highest speed frame-sync mode. DOUT1 can be directly connected to the MISO input of the host processor.

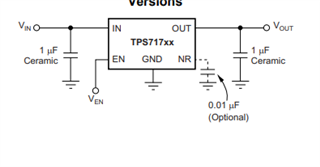

7. DVDD, pin 26, is an internal digital supply for the ADS1278. This pin must be supplied by a regulated voltage source. Please add an additional power supply use a linear regulator to generate a stable +1.8V supply.

8. CLK, pin 27, needs to be a continuous clock. The specific frequency of this CLK depends on the output data rate and desired mode of operation. If operating in high speed mode, then setting this clock to 27MHz will result in an output data rate of 105ksps.

9. DRDY pin 29 needs to be connected to the host processor.

10. AVDD pins 44 and 53 need to be connected to the +5V supply. A 0.1uF supply bypass capacitor for each of these pins should also be added.

Regards,

Keith Nicholas

Hello Keith,

Good day.

Hello,

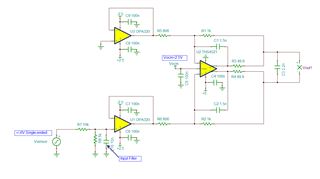

The input buffer circuit looks correct. There is one error; the shutdown pin 5 for the OPA320S devices must be connected to V+(pin 6) in order to enable the amplifier. Pin 5 (SHDN) connect be left floating

Everything else looks good at this point in the design.

Regards,

Keith

Hello Keith,

Good day.

Hello,

Using a 27MHz clock, (Pin 27 supplied with a continuous 27MHz clock), the output data rate in High-Speed mode (pins 33 and 34 connected to ground) will result in an output data rate of 105.469ksps. This output data rate determines the bandwidth of the digital filter, which is equal to 0.49 of the data rate, or:

f-3dB=105.469*0.49=51.7kHz. The maximum bandwidth of the SDI sensors appears to be less than 4kHz, so you have more than 10x the bandwidth needed for these sensors.

Based on the latest version of the schematic, I see that the SCLK and CLK pins are tied together. These pins should be separated, and a 27MHz clock oscillator connected directly to the CLK pin 27 of the ADS1278.

Regards,

Keith

Hello Keith,

Good day.

Hello,

1. Looks correct.

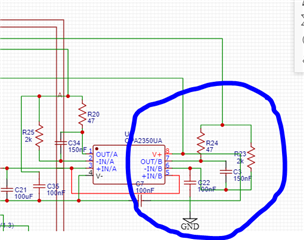

2. Yes, the +InA/+InB can be connected to the same node in the circuit. Each of these pins are high input impedance and will not load the output of the RC filter (filtered version of the reference voltage). However, it looks like you have a schematic error. C35 should be connected on the other side of R25.

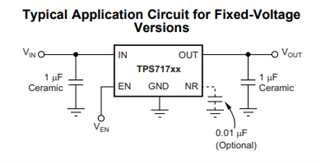

3. TPS71718 is the fixed 1.8V output version of this device. You do not need to connected an external resistor network to the FB pin. In fact, pin 4 for the TPS71718 is a noise reduction (NR) pin, and can either be left floating or connected to a 10nF capacitor to ground to further reduce noise.

You will need to estimate total current requirements and determine an appropriate power limit for your system. I would budget at least 100mA for the 5V supply.

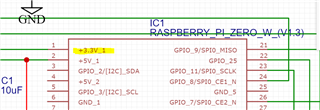

4. The clock oscillator needs to be powered from the same supply voltage as connected to IOVDD. In your case, this clock oscillator needs to power from the +3.3V supply.

Regards,

Keith

Hello Keith,

Good day.

Hello,

The output voltage of the clock oscillator must be the same voltage levels as the IOVDD supply voltage. If you use a +1.8V clock oscillator, then IOVDD (and the digital signals from your processor board) must use 1.8V logic levels. Based on your schematics, you have IOVDD connected to a +3.3V supply. If this is the case, then the clock oscillator must operate from a +3.3V supply as well.

The ADS1278 sets the output data rate based on the clock frequency (f-CLK), the CLKDIV level, and the MODE selection. The maximum possible data-rates are displayed in Table 8.

If you only need 200sps, then I would suggest using the Low-Speed mode (MODE0 pin34 logic high and MODE1 pin33 logic high), and reduce the CLK pin frequency as follows:

f-DATA=f-CLK/2560 for Low-Speed Mode, CLKDIV=1.

f-CLK=f-DATA*2560=200*2560=512kHz. If you use a standard 1MHz frequency clock, then your data rate will be:

f-DATA=1MHz/2560=390sps.

In order to allow flexibility in the data rate, you may want to use pull-up and pull-down resistors for pins 33 and 34 to allow different speed mode configurations.

The ADS1278 constantly converts data, pulling /DRDY pin29 low when data is ready to be read from the device over SPI. The processor needs to monitor the /DRDY signal and transfer data after /DRDY goes low.

Regards,

Keith

Hello Keith,

Good day.

Hello,

Yes, any clock oscillator specified for +3.3V operation that provides a CMOS output can be used. HX2127002Q or HSO321S_27MHz can be used. The ADS1278 controls the data rate based on the f-CLK frequency, and the CLKDIV and MODE pin settings.

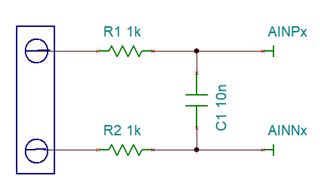

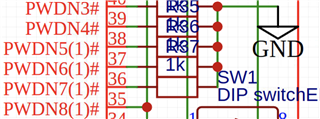

If you want to use the unused ADC channels, you will need to enable them by connecting the PWDNx to +3.3V. For any unused channel, I suggest adding an RC filter between the screw terminals and the AINPx and AINNx inputs.

Below is my review of your schematic:

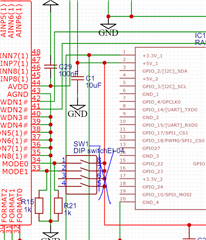

1. Adding R15 and R21 as pull-down to the MODE pins and the dip switches is correct. However, the DIP switch needs to connect to the +3.3V supply, not the +5V supply as you have drawn in your schematic.

2. The clock oscillator OE pin 1 should either be connected to VDD (+3.3V) or left floating to enable the output of the oscillator.

3. ADS1278 AVDD pin 44, REF5020 VIN pin 2, and OPA2350 V+ pin 8 need to be connected to the +5V supply. Your schematic just has these connected to each other, but not to the +5V supply pin from the processor board.

Regards,

Keith

Hello Keith,

Good day.

Hello,

The VCOM buffer is connected incorrectly. VCOM pin55 on the ADS1278 is an output, and should be buffered by U5B, and then drive the Vocm pins of U4 and U12 (THS4521).

Here is the correct schematic connection:

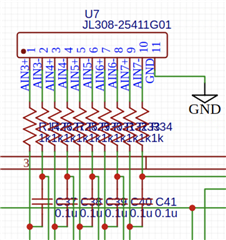

Also, if you want to use the extra channels, AIN3.....AIN8, then you need an option to power-up these channels. Your current schematic has channels 3 through 8 powered down by connecting PWDN3 through PWDN8 pins directly connected to ground. I suggest adding pull-down resistors (1kohm to ground) to each of these digital inputs so you have the option to power these channels ON at a later time.

Regards,

Keith

Hello Keith,

Good day.

Hello,

The VCOM pin on the ADS1278 is an OUTPUT signal. It is a high impedance output, which is why it needs to be buffered using an amplifier. The output of the amplifier then drives the VOCM INPUT pins on the THS4521 amplifiers.

Your schematic updates look correct. The PWDN pins need to be connected to IOVDD (3.3V) if you want to enable those channels. By adding the 1k pull down resistors, the channels will default to off, but if you remove these and add a jumper to the PWDN pin and IOVDD, then you can enable these channels. If preferred, you can add another switch like you did for the MODE pins to easily enable these channels. Another option is to connect these pins to unused GPIO channels on the RPi board, similar to what you have already done for PWDN1 and PWDN2 pins.

Regards,

Keith