Other Parts Discussed in Thread: DAC8771,

Dear Sir,

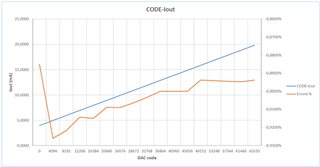

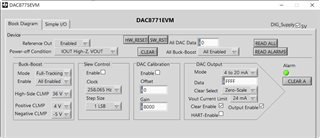

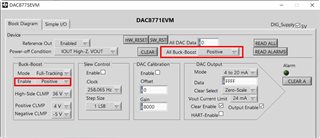

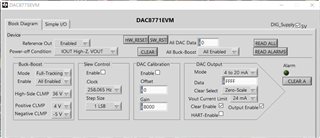

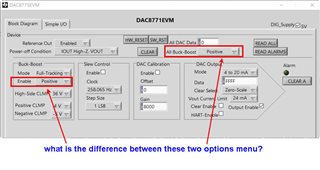

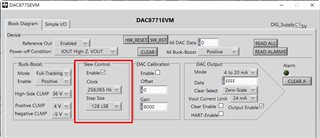

I'm doing first testing with the EVM, 12V input supply, output 4-20mA. Touching the DAC reveal that this is hot with the DIG_supply checkbox is selected (related right label report 5V), when I uncheck this box label report 3.3V and then the chip is no more hot.

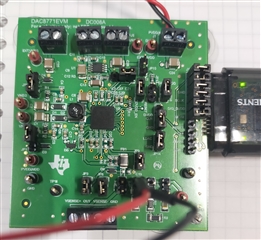

Here below my actual jumper settings:

JP1: 1-2

JP2: 1-2

JP3: installed

JP4: not installed

JP5: installed (load 249ohm)

JP6: not installed

JP7: not installed

JP8: installed

JP9: installed

JP10: not installed

JP11: 1-2

JP12: 2-3

JP13: not installed

JP14: installed

JP15: not installed

JP16: not intalled

JP17: unable to find it inside the board...

So you have some hint, note?

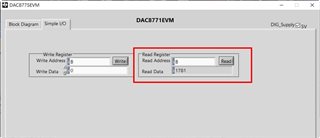

Also READ ALL active every time HART-Enable despite I've unchecked the relaterd box...

Thanks and best regards.

FF