Other Parts Discussed in Thread: ADS124S08

Hello Texas Instruments Support Team,

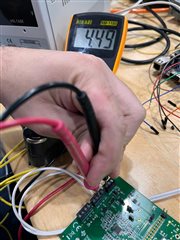

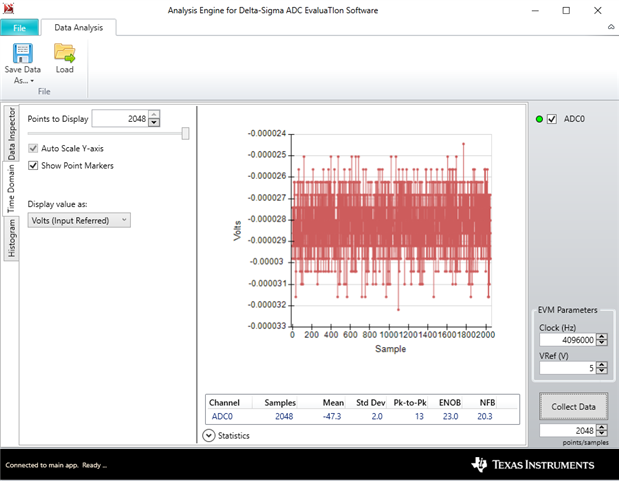

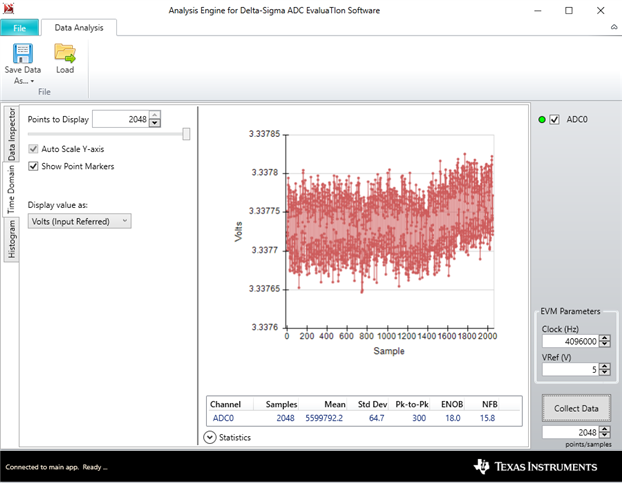

I am currently working with the ADS124S08EVM and have encountered an unexpected behavior during signal readout. I connected a 4.5V battery across input pairs AN0(+) and AN1(-), as well as AN10 and ANCOMMON, for differential measurement.

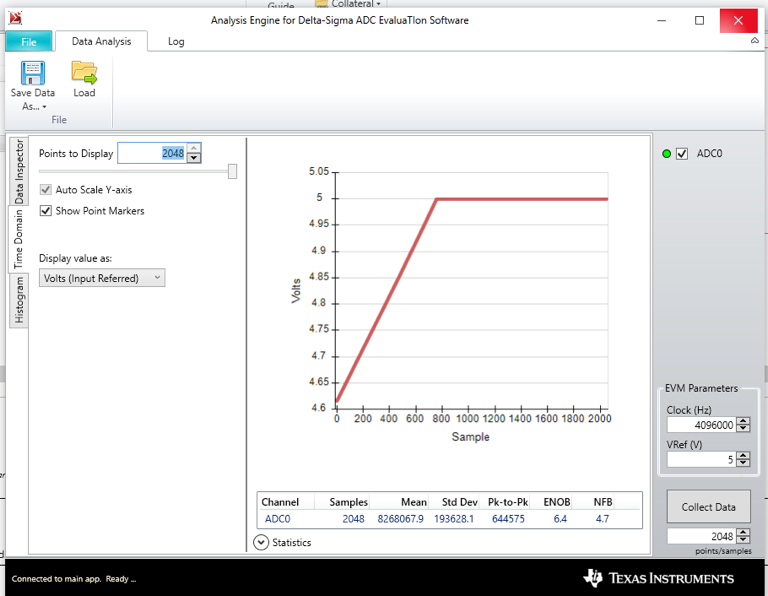

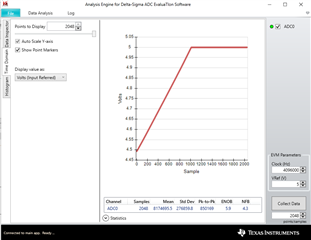

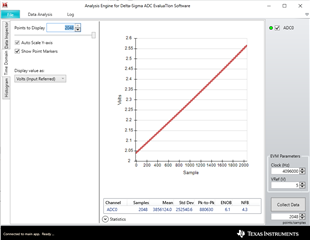

Using the TI evaluation software, the readout initially displays the correct voltage of 4.5V. However, after a certain number of samples, the readings begin to ramp up linearly and eventually saturate at 5V, the VREF I set in the software. I’ve attached a screenshot from the evaluation software showing the observed behavior.

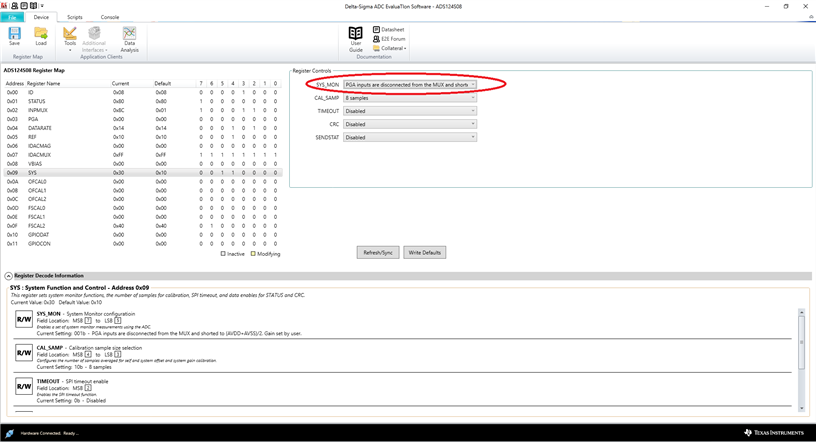

Configurations are default set, only changed the input and sample rate (for tests)

• VREF: 5V

• Clock: 4096000 Hz

• Input Channels: AN0(+) with AN1(-) and AN10 with ANCOMMON

Could you please assist me in understanding the potential causes of this issue? Are there any steps I should follow to resolve this?

Warm regards,

Artur