Other Parts Discussed in Thread: DLPC350, TPS54620, DLP4500

Dear TI E2E Community,

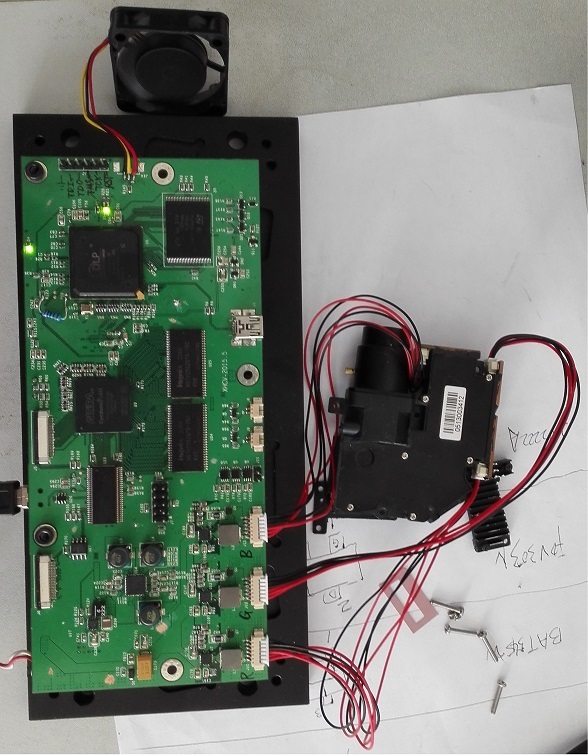

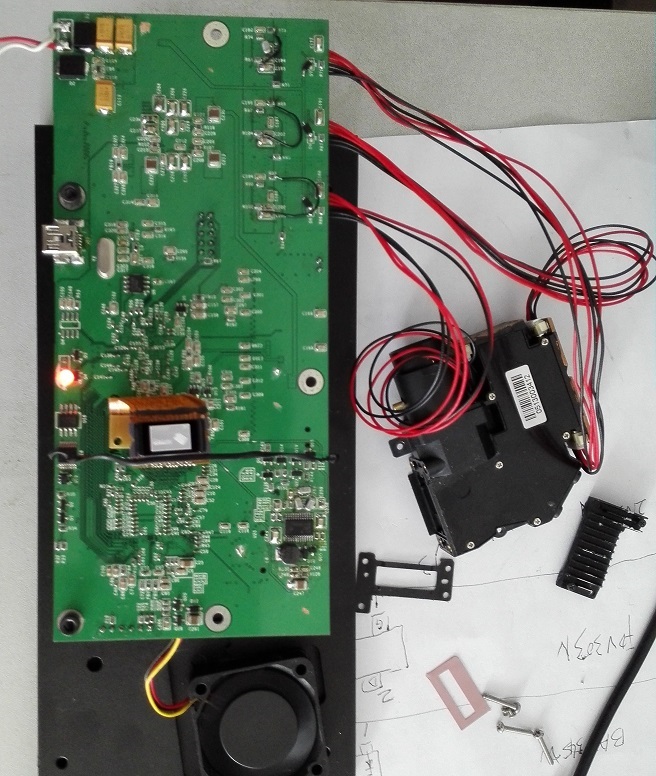

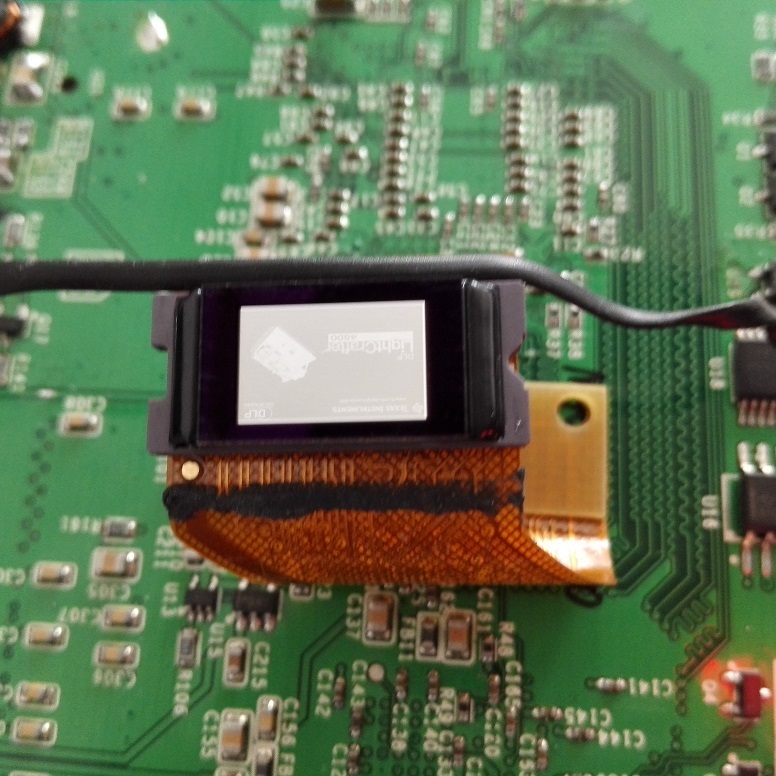

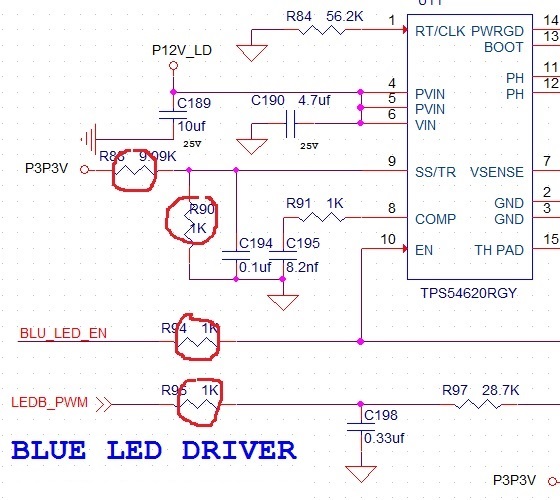

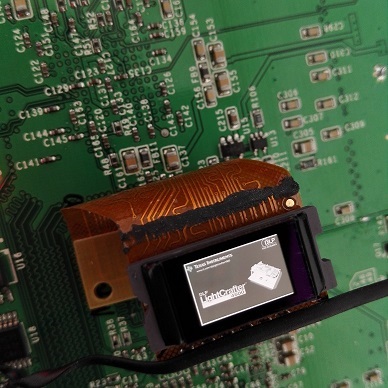

I am developping my own DLPC350 board.

The first thing is programming the empty flash chip. In the forum, "JTAG flash programming utility from TI", where can I find it? Does it mean "DLPC350 BSDL" in "www.ti.com/product/DLPC350"?

I have altera usb blaster in hand, can I program the empty flash with "flash programmer from TopJTAG " and the alter-usb-blaster?