Other Parts Discussed in Thread: TPD4E004, TPD4S012

Hello Team,

We have a PCB with the MCU MSP432 and all the IO pins are taken to another board through a connector.

Both the boards are powered independently and all the IO pins are isolated.

Al the signals are at 3.3V logic.

1). Where should we place the ESD diodes?

On the board containing MSP432 or the other board?.

2). We have SPI, UART, I2C, USB and CAN signals to the second PCB.

What kind of ESD Diodes do we need to use?. Unidirectional or bidirectional.

3) Can you please let us know the difference between the following?.

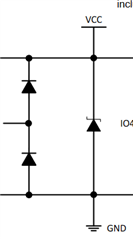

a).

The above is a bidirectional diode

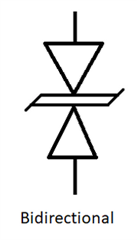

b).

The above is a bidirectional but its anodes are connected together.

c).

The above is also a bidirectional but its cathodes are connected together.

In some ESD diode datasheets, I have seen some diodes with clamping voltage lower than working voltage. Why is that?.

Looking for your reply