Part Number: THVD8000

Other Parts Discussed in Thread: THS6222, THVD8010

Tool/software:

Hi,

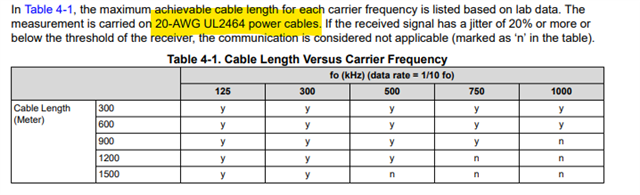

in my Building Automation / HVAC application Imight have up to 30 nodes, the protocol is Modbus 9600b/s, the power cable maximum lenght could be 300 meters.

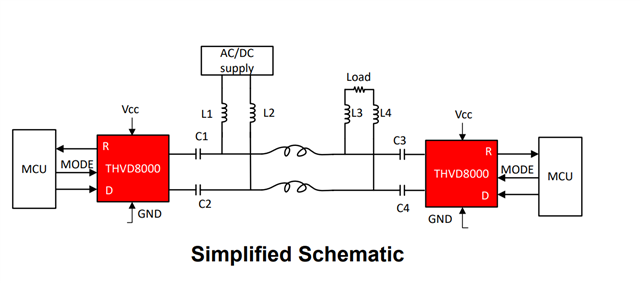

I would like to know if the THVD8000 can be used in such an application where, instead of using the 4 wires Modbus RTU cable to interface the several sensors and thermostats with the Control Unit, you can use the power line (230V). Or the 24VDC?

Thanks.

Michele Ammendola