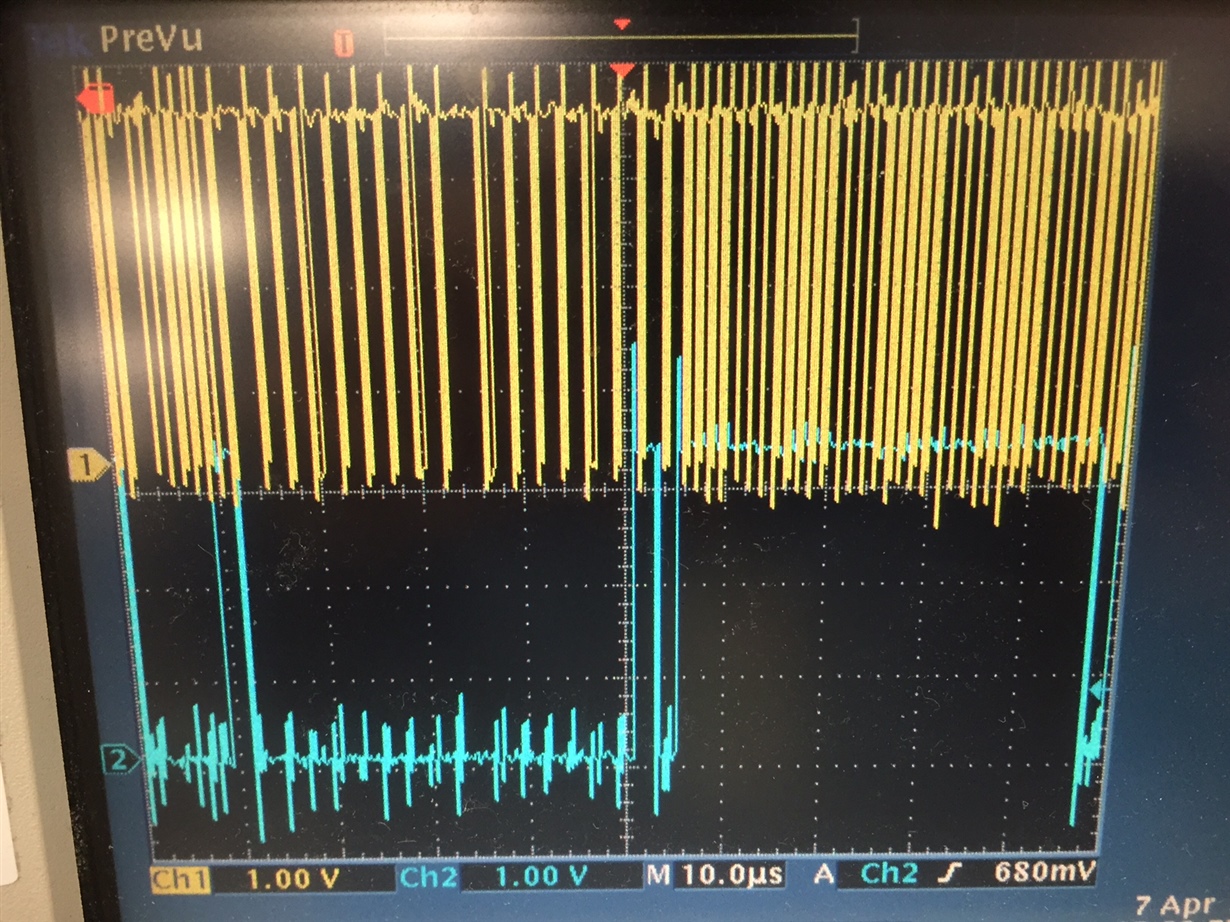

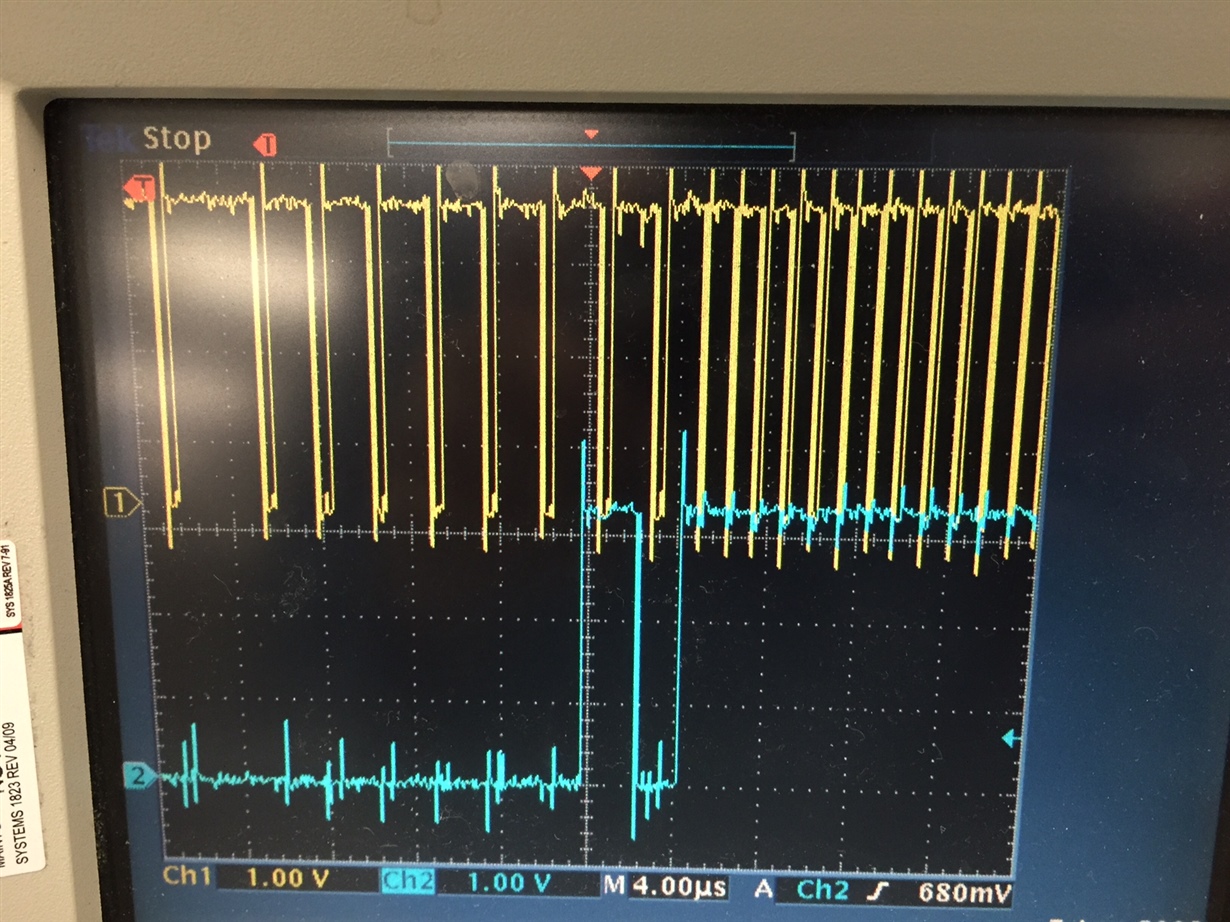

Below are screenshot of the MDC and MDIO signals from the USB Dongle from the TLK10232 Development kit. I am having issues talking to the TLK10232 and want to verify that the mdc and mdio signals are correct. The MDC clock doesn't look periodic with 50% duty cycle. Is this okay?

-

Ask a related question

What is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.