Hello.

I know, that Cortex-M3 devices from TI have NRND status. But they are still available on the market, and questions regarding them appear fairly often.

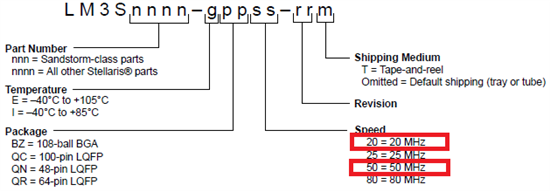

Is there any document, which describes differences between LM3S818-IQN20-B0P and LM3S818-IQN50-C2?

The reason of this question is next:

there is a development kit for motor control - RDK-ACIM ,

which is based on LM3S818-IQN20-B0 device on the main board.

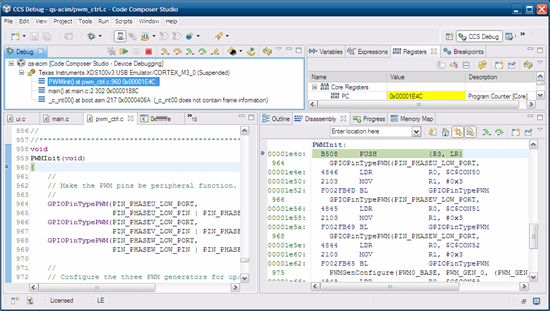

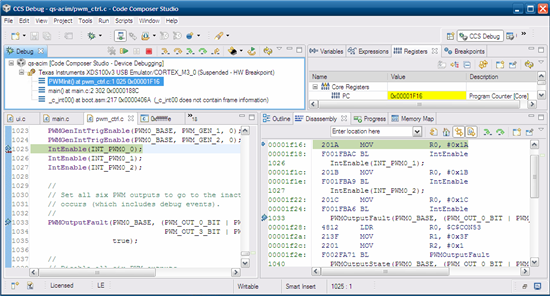

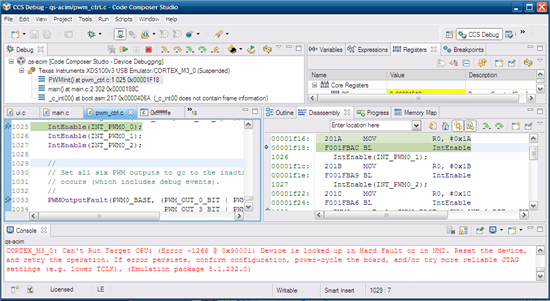

This design was repeated for educational purposes on LM3S818-IQN50-C2. But software doesn't work on this design. Furthermore, debugging in CodeComposerStudio 5.5 is very complicated because of huge amount of "hangs out".

So, which changes shoul be done to make RDK-ACIM software to work on LM3S818-IQN50-C2?

Thanks for help ahead of time.