Hello,

I am trying to run is04_signal_chain_test_eabi from MotorControl SDK Version 4.02.01. So far, I have been able to spin the motor in open loop using is03_signal_chain_test_eabi.

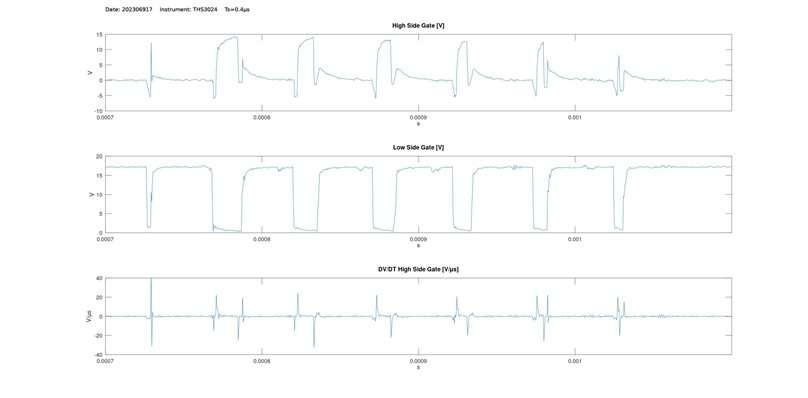

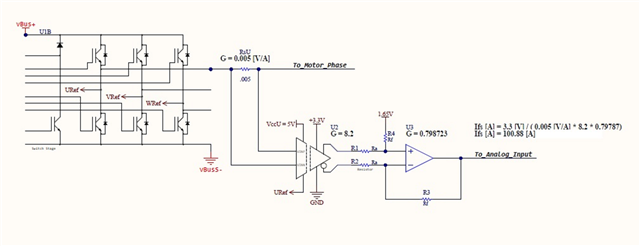

As far as I can presume, the parameters for voltage and current feedback are correct. The PWM signal is running at 20KHz with a dead time of 2.5µs. The rise DV/DT of the gate voltage is currently about 20 V/µs.

Given all this conditions, when I try to spin the motor using is04_signal_chain_test_eabi, the motor just make a click noise but doesn't start. The IGBT Gate Drive, goes to protection mode and shuts off the gates.

My assumption is that, at the time of failure, the duty cycle of the high side PWM signal is too short and the gate voltage never raises above the minimum switch voltage and the high side IGBT never turns on. The IGBT Gate Driver checks the IGBT's Vce. Because of the fact that Vce doesn't drop after an specified time (Vce should go below 9V after 250ns), the divers detect a short circuit condition and shut down the output.

Could you please give me some insight on what is happening? Is there any mechanism to control the duty cycle of the PWM signal? Is the PI controller already saturating? How can I check if the PI controller is saturating?

For reference, these are the gate voltages. IGBT threshold voltage is 6.5V.