Other Parts Discussed in Thread: DRV8353

Hello team,

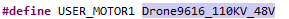

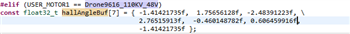

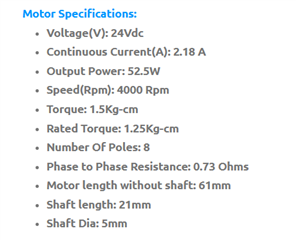

As we work on developing the custom board, we tested it with the DRV8353 and the f2800157 launchpad to ensure that the motor operates properly before moving on to the custom board.

1) encountering problems when using a motor. The motor makes one complete spin in the opposite direction before running at the specified speed on the first try when we set a positive speed_ref value. What criteria must be followed in order to lessen this rotation in the other direction?

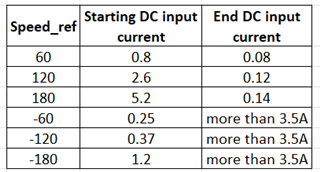

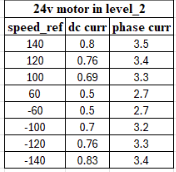

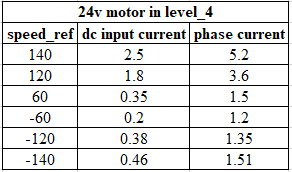

2) Another problem I'm having is that the motor won't start when I set the speed_ref value to zero, even though it's drawing greater current from the supply—more than 19 amps—and I have the same problem when I set the negative speed_ref value.

3)We are seeing the same problem as before, where the motor starts and rotates fully in the other way. I have activated POT in the UMC, and I can now control the motor speed using POT.

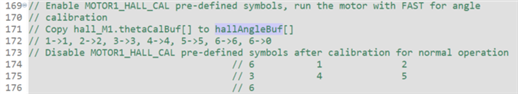

What parameters should we calibrate for this, in your opinion?

3)is there any way to control motor torque and which are the calibration parameter is required to change motor torque.

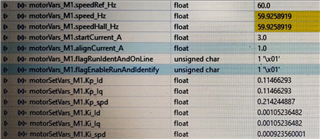

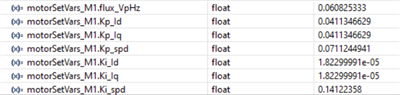

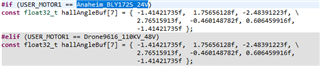

4)if motor parameters are updated and make motor_identifications = true, no need to identify again but still expression windows not showing the updated value from user_mtr.h .

every time need to enter the motor parameter values in expression window. Which is not updated directly from user_mtr.h

Thanks in Advance

Regards

Kirana H P