Other Parts Discussed in Thread: TMS320F28379D

Hi TI

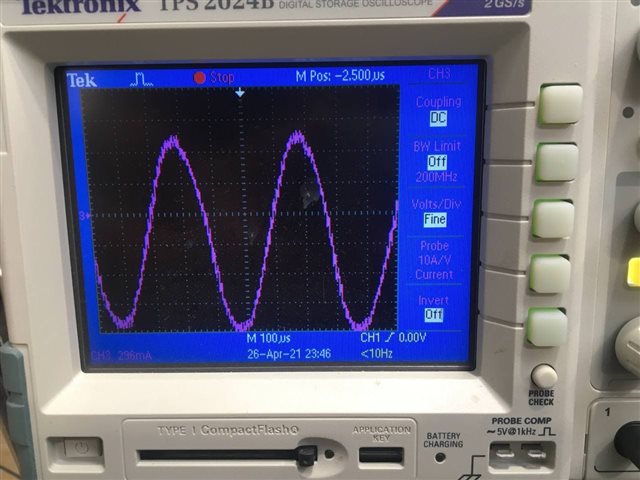

For our high speed, ultra-low inductance motor the switches burst instantly in the first pulses.

we ran a motor with inductance of 300 uH successfully but for the following one the power switches explode everytime.

The inductance is 47 uH.

#define USER_IQ_FULL_SCALE_FREQ_Hz (1400.0)

#define USER_ADC_FULL_SCALE_VOLTAGE_V (120)

#define USER_IQ_FULL_SCALE_CURRENT_A (250.0)

#define USER_ADC_FULL_SCALE_CURRENT_A (250.0)

#define USER_PWM_FREQ_kHz (100.0)

#define USER_MAX_VS_MAG_PU (0.6666)

#define USER_NUM_PWM_TICKS_PER_ISR_TICK (3)

#define USER_NUM_ISR_TICKS_PER_CTRL_TICK (1)

#define USER_NUM_CTRL_TICKS_PER_CURRENT_TICK (1)

#define USER_NUM_CTRL_TICKS_PER_EST_TICK (1)

#define USER_NUM_CTRL_TICKS_PER_SPEED_TICK (90)

#define USER_NUM_CTRL_TICKS_PER_TRAJ_TICK (90)

#define USER_R_OVER_L_EST_FREQ_Hz (300)

define USER_ZEROSPEEDLIMIT (2 / USER_IQ_FULL_SCALE_FREQ_Hz)

#define USER_VOLTAGE_FILTER_POLE_Hz (1200.0)

#define USER_MOTOR_TYPE MOTOR_Type_Pm

#define USER_MOTOR_NUM_POLE_PAIRS (1)

#define USER_MOTOR_Rr (NULL)

#define USER_MOTOR_Rs (0.02)

#define USER_MOTOR_Ls_d (0.000047)

#define USER_MOTOR_Ls_q (0.000047)

#define USER_MOTOR_RATED_FLUX (0.0148)

#define USER_MOTOR_MAGNETIZING_CURRENT (NULL)

#define USER_MOTOR_RES_EST_CURRENT (1.0)

#define USER_MOTOR_IND_EST_CURRENT (-0.5)

#define USER_MOTOR_MAX_CURRENT (100)

#define USER_MOTOR_FLUX_EST_FREQ_Hz (20.0)

Does anyone have a similar experience? What could be done to prevent this and run the motor.

Many thanks