Hi,

I am designing the schematic for F28377D and taking the F28377 ControlCard as reference.

In the F28377 ControlCard the ADC module uses two ref3030 and a 4ch rail-to-rail input and output precision amplifier LMP7709 as voltage followers to set the reference-high.

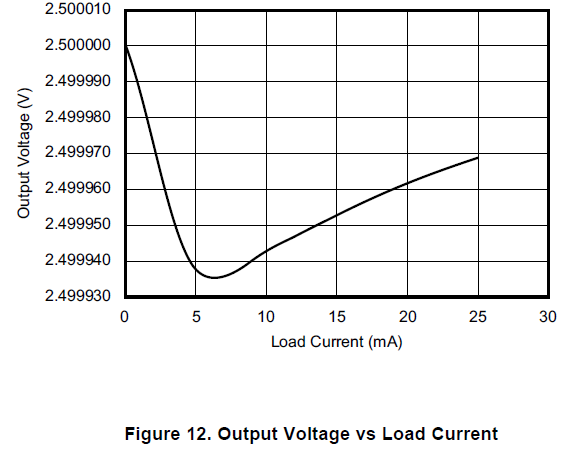

But I think the accuracy and output current is high enough for the ADC module and I consider that I do not need the voltage followers to achieve the impendance matching.

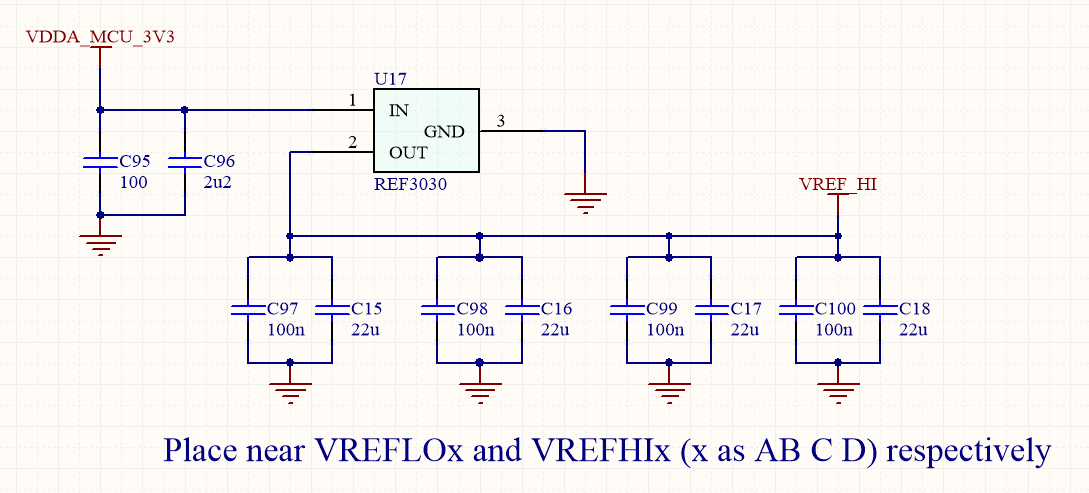

So the ADC reference-high setting can be done as below. A 22uF capacitor for the 16-bit mode.

Is there something wrong with my design? Are these voltage followers necessary?

Looking forward to your reply.

best regards,

Di