Other Parts Discussed in Thread: HALCOGEN

Tool/software: Code Composer Studio

Hi ALL,

I have some questions about using TMS570 for BMS

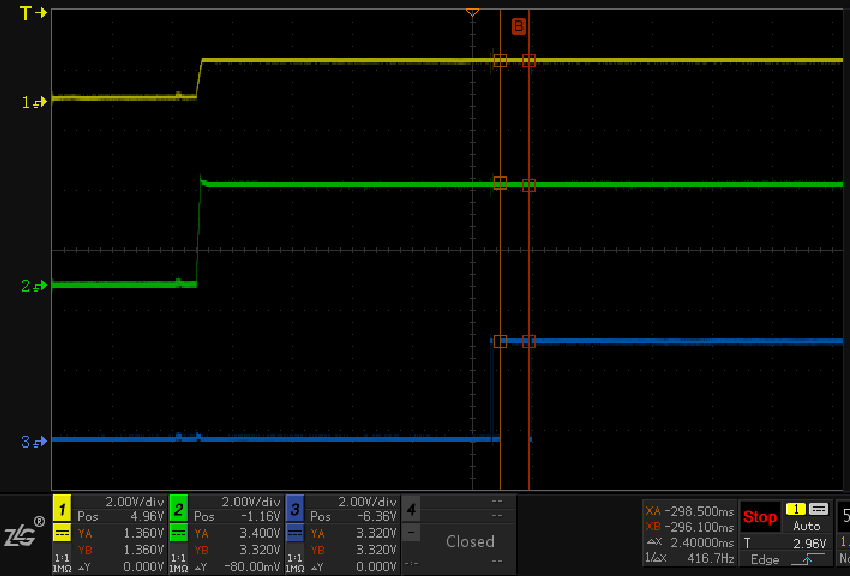

1.I found it in the safety Handbook. TMS570 after the completion of the electrical self-test, will be through the nerror foot output a low pulse, and the actual measurement of output of 2 low pulse, I would like to ask whether this is normal, which Yellow line for 1.2V power supply, Green Line for 3.3V power supply, Blue line for the nerror output. is the external circuit to the TMS570 self-test after the output of this nerror to do testing, not to do the test to meet the safety design requirements?

2.I see in the datasheet that ADC has two kinds of self-test, normal self-test and median self test. The functions produced by Halcogen correspond to void Adccalibration (adcbase_t *adc) and UInt32 adcmidpointcalibration (adcbase_t *adc), respectively, Excuse me these 2 kinds of self-test way is to use only one or two kinds of use, in the use process what request?

3.I am in Halcogen configuration PWM capture, choose black box mode, what is the principle of this mode to achieve capture? Not found in the reference manual.

invoking void Capgetsignal (hetrambase_t * hetram, UInt32 cap, hetsignal_t *signal) in a Halcogen-generated drive can achieve PWM capture, change the PWM duty ratio, and achieve dynamic capture. When the PWM signal input is removed, the function is called to find the period and duty ratio or the value before the PWM input is disconnected. How does this work out?