Hi Team,

Good day. I am posting this inquiry on behalf of the customer.

I've constructed a basic capacitive sensor, which features a flexible silicone material encapsulated between an upper copper layer and a lower copper layer, forming a cylindrical shape.

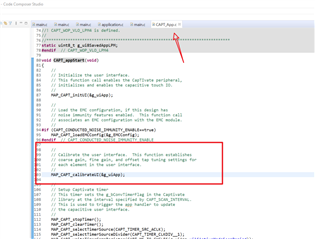

With a motorized pressure machine, I apply varying levels of pressure and assess the sensor's output from 0.25 to 5 kg in increments of 0.25 kg, using the TI Captivate design software. As anticipated, the sensor's output declines in a non-linear fashion as the weight increases. I've also conducted a repeatability test, which proved successful. To illustrate, I repeatedly applied the same weight (for example, 1 kg 10 times), and consistently achieved the same output.

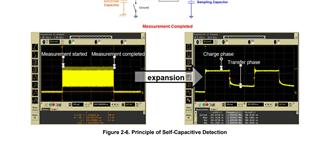

Nevertheless, I've encountered an issue. When I apply a weight of 5 kg and then swiftly reduce it to 1 kg, the sensor's output value differs from the original measurement. This implies that the output curve I get when decreasing the weight from 5 kg to 0.25 kg differs from the curve obtained when increasing the weight, similar to a hysteresis curve. This would entail measuring the sensor's output at 3 kg, raising the weight to 5 kg, and then immediately dropping it back to 3 kg. At 5 kg, the distance between the plates is minimized, leading to the capacitor getting charged, and even when the weight is reduced (which increases the distance between the plates), the capacitor may not discharge sufficiently.

I'm curious about the root cause of this problem and the methods I could use to achieve the same values for a specific weight, irrespective of whether the weight is increased or decreased. Could it be due to the effects of charging and discharging?

Is there any way to discharge capacitors using the code?

Please help to advise. Thank you for extending your support.

Kind regards,

Marvin