Hi community member,

I’m comparing MSP430FR2433 and MSP430FR5969.

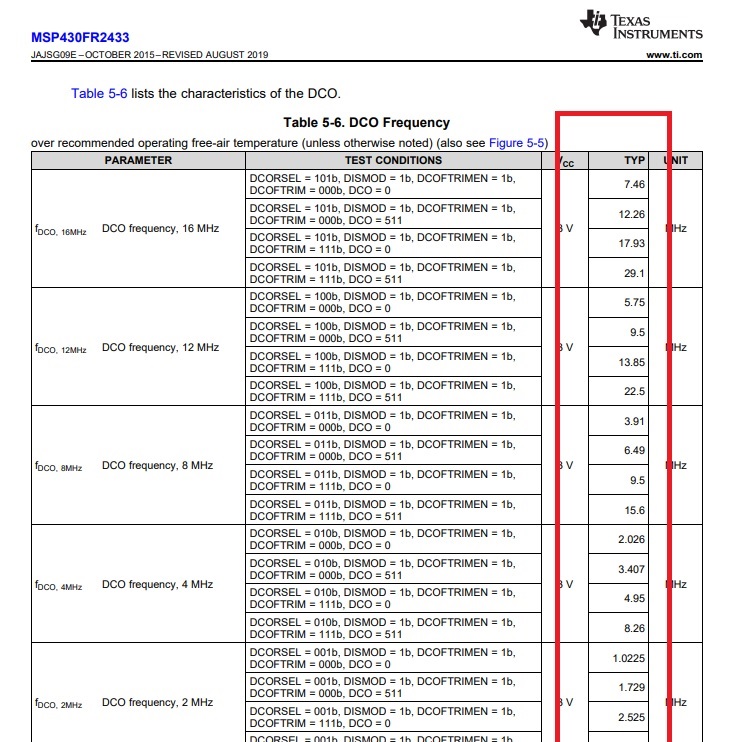

The MSP430FR2433 DCO shows "Typical" in all frequency ranges.

Because MIN and MAX are not listed, does TI not guarantee the oscillation frequency of MSP430FR2433 DCO?

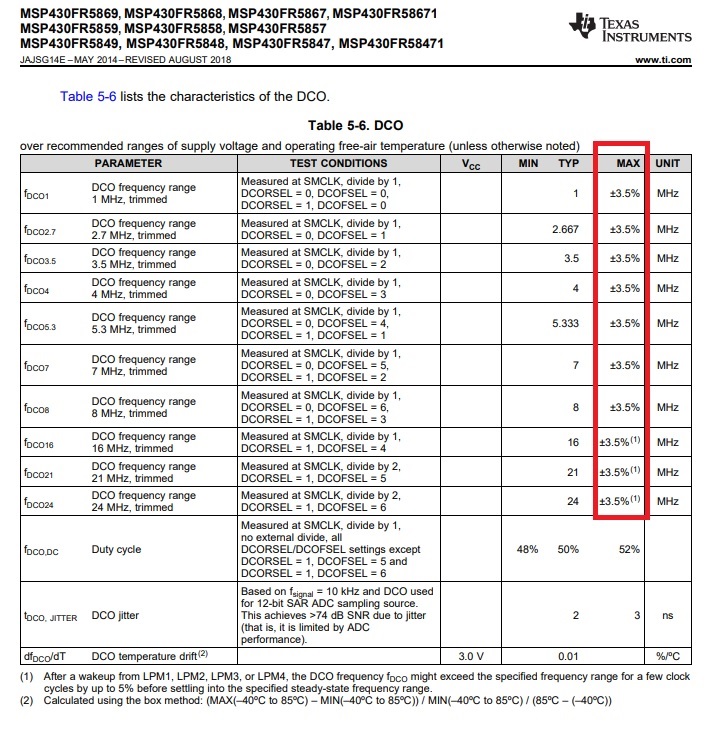

The MSP430FR5948 is described in the data sheet as follows:

If it is MSP430FR5948, can I tell my customer that TI "guarantees" the oscillation accuracy of the internal clock?

Best regards.

Cruijff