Other Parts Discussed in Thread: CAPTIVATE-PHONE, CAPTIVATE-FR2633, CAPTIVATE-BSWP, BOOSTXL-CAPKEYPAD

Hi,

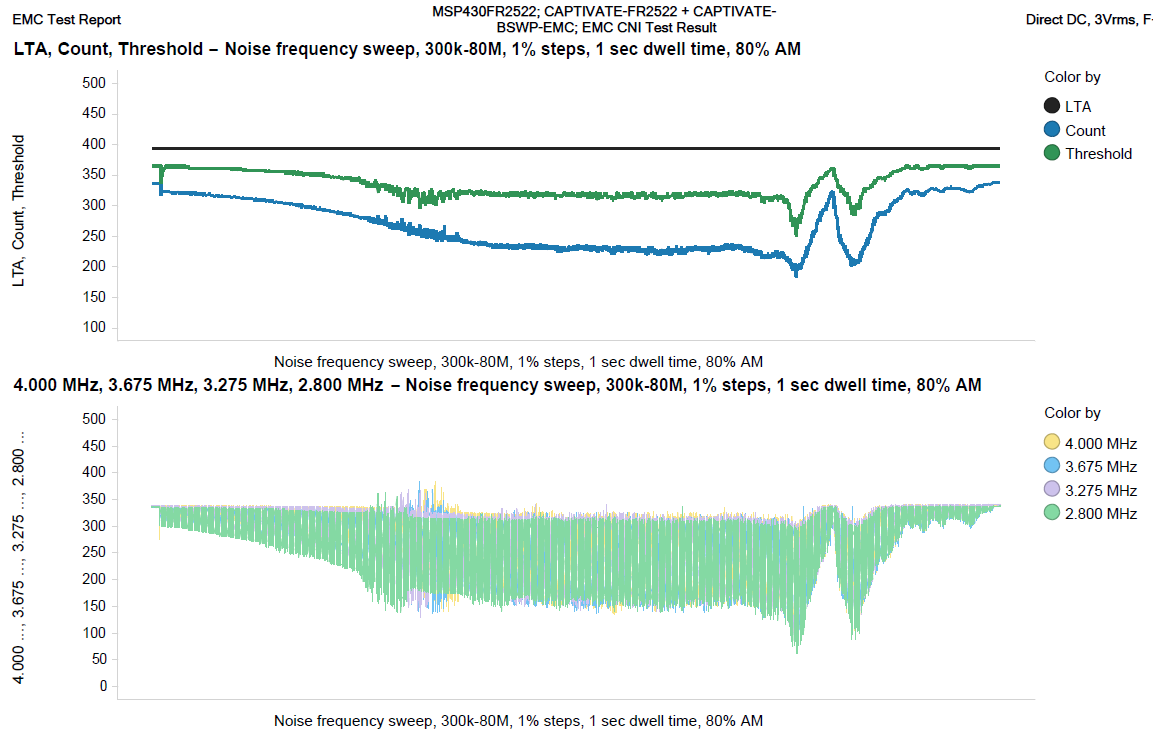

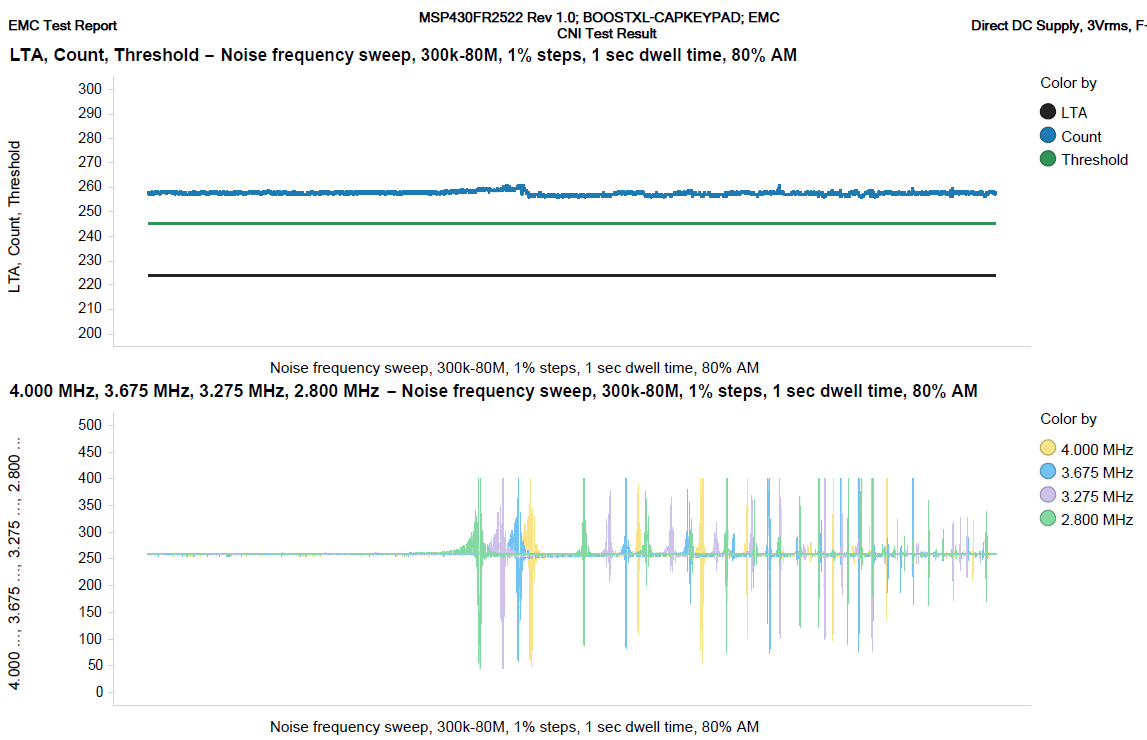

I tested the MSP Captivate MCU – Phone Demo Board Revision E with current injection 3V RMS. We used the software generated by the Design Center version 1_60_00_00 with the enabled flag of noise immunity. The Active Mode Scan Rate is set to 40ms.

When I slide the scrollWheelSensor we see that some numericKeypadSensor are activated at the stress test frequency of 4MHz. Why is there some crosstalk under the test stage with 3V RMS common mode noise?

We are planning to use the devices for HMI Panel for household appliances and need a stable system even with current injection according to IEC 61000-4-6 conducted noise immunity 3Vrms.

What can we do to get the noise immunity of 3V RMS common mode noise?

In which steps jumps the frequency hopping? Is the frequency hopping not working?

We need some support at our location in German. Has TI an engineer in Germany who can help us with the noise immunity issues?

Thanks