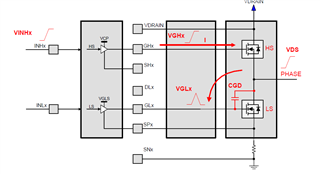

Other Parts Discussed in Thread: DRV832X

Hello team,

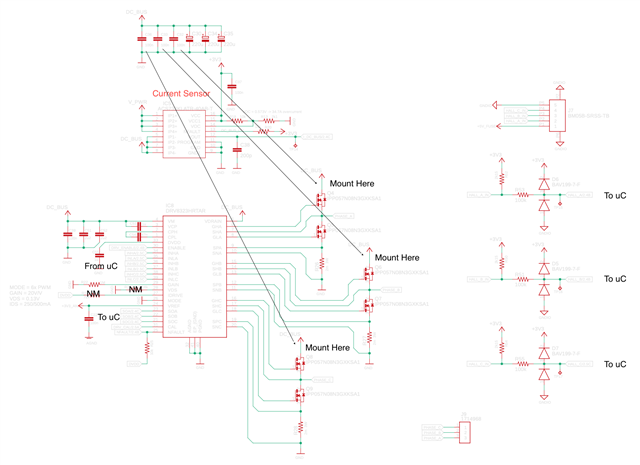

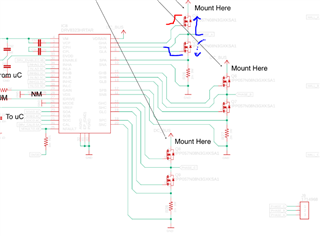

I am using the DRV8323HRTAR (no SPI) to drive a BLDC motor.

While the motor spins, it makes a strange rattling noise and I am trying to solve this issue.

I have implemented a trapezoidal upper modulation control with speed retroaction.

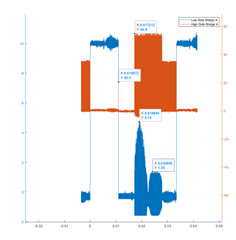

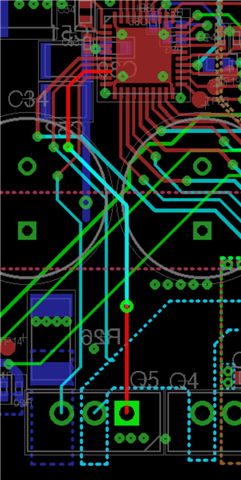

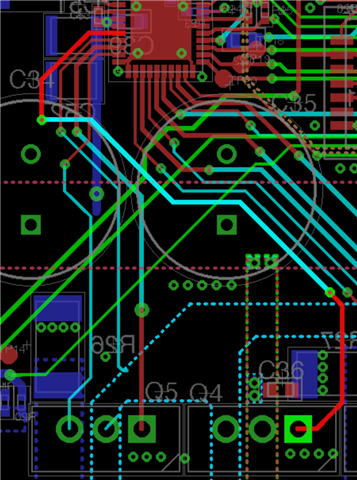

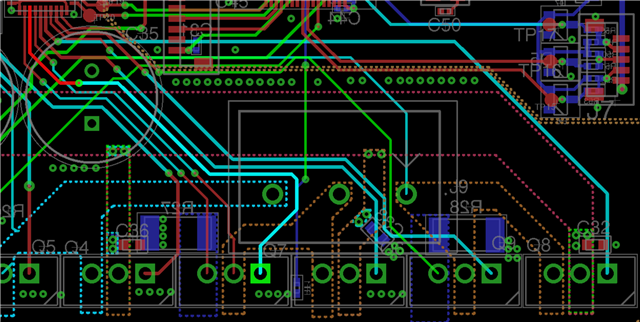

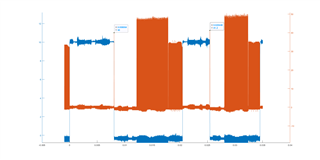

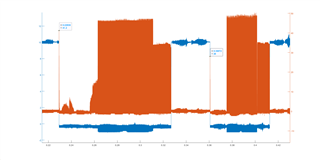

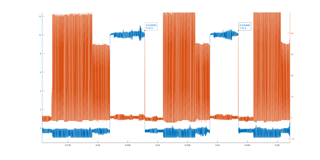

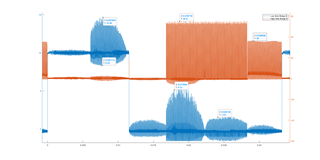

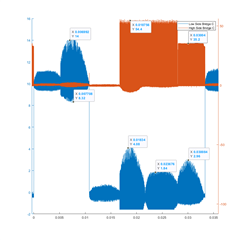

Analyzing some data (2-ch scope and CAN at 1ms cycle time) I am noticing that:

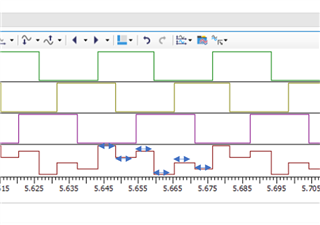

- Bridge A is behaving differently than B and C

- Every time I turn off a low side mosfet, there is a voltage spike on the high side voltage gate

- While the high side mosfet is on, also the low side is on

CAN Data:

SOx = current measured via the shunt resistor by the DRV

Scope Data:

- All the waveforms are the gate voltage measured with reference to ground

The DRV is configured as follow:

- GAIN = 20V/V

- MODE = 6x PWM

- IDRIVE = 120/240mA

- VDS = 0.6V

- Shunt = 2mohm

- No fault triggered by the NFAULT pin

Please let me know if you need any additional information.

Thank you

Simone Palombi