Other Parts Discussed in Thread: CSD88537ND,

Hi,

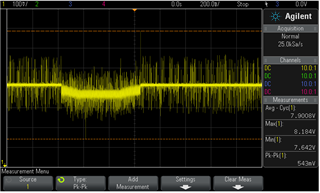

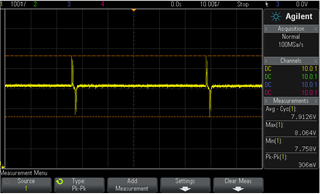

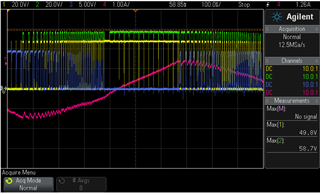

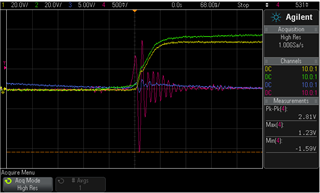

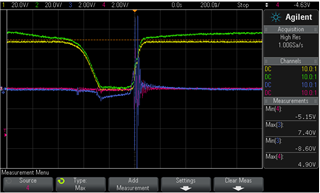

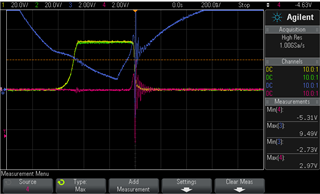

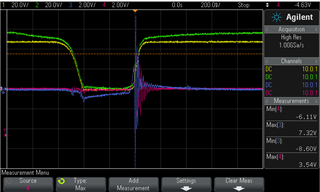

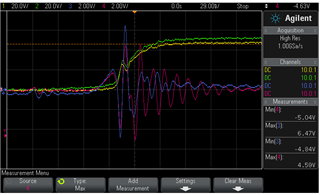

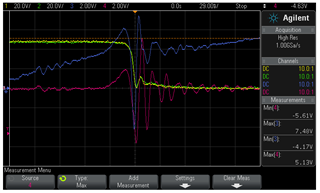

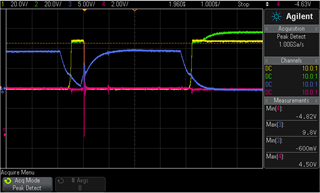

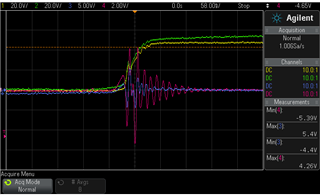

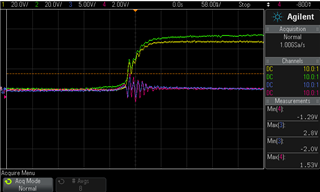

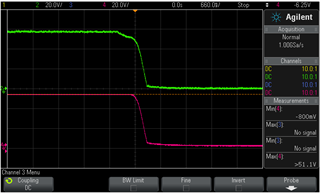

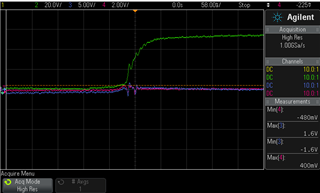

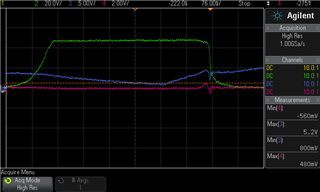

We have issues with the DRV8711 where in some cases it gets damaged: once current regulation is enabled (CTRL.ENABLE=1) an overcurrent error is triggered. Lowering current setpoint (CTRL.ISGAIN, TORQUE) or increasing OCP settings (DRIVE.OCPTH, DRIVE.OCPDEG) does not help. We have to replace the DRV8711 IC to fix the issue so it seems that the IC gets damaged. It also happens when starting motion (pulses at STEP input). In some cases a predriver fault is triggered.

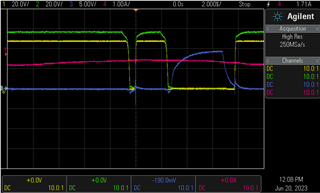

We use different decay modes for standstill and motion, mostly to lower standstill noise.

It is hard to reproduce the issue at our department: it happens now and then at customers.

Our design:

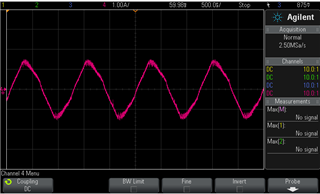

Steppermotor NEMA 17: bipolair, 1.5 A/phase, 2.4 Ohm/phase, 2.6 mH/phase

Drivervoltage/VM: 48V

FETs: TI CSD88537ND

Rsense: 0.05Ohm

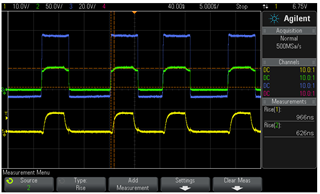

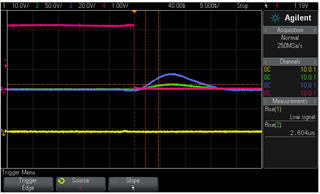

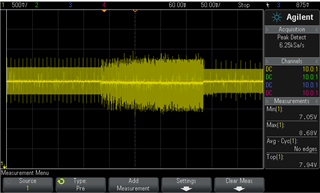

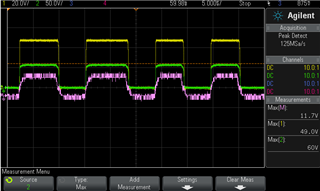

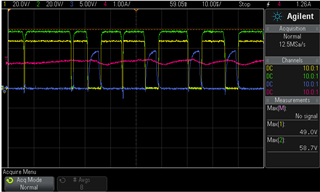

We've optimized DRV8711 settings based on audible noise and smoothness of the current curve (measuring FET output current on scope):

DRV8711 motor hold (standstill) settings:

DRV8711 motor run settings (max : 53000 steps/s)

Equal to the above, except:

- Decay mode: mixed

- Blank time: 2.0µs

- Off time: 4 µs

Can you explain what happened to the damaged DRV8711? Can it be a temperature issue?