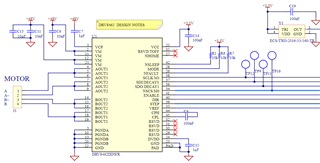

We have this driver set up with a STM uP. We are noticing that is getting rather hot when the TI's eval board stays relatively cool. What would be some items to look into to ensure we're set up correctly?

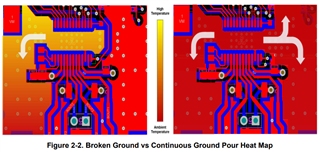

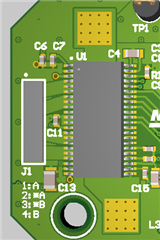

Looking at design comparisons (ours vs TI-eval) they are relatively similar. We are going to run a thermal camera on this soon to see where heat is generating from. I'm curious if there are particulars about this setup for our firmware and how we drive this driver. If anyone has input or past working with this device (or in general) I would greatly appreciate it. We're kinda scratching our heads why this is rather warm. We even added extra breakout for thermal pad (gnd) to have our heatsink apply to both the top of the device (with thermal pad) and then to the exposed square pads (with thermal grease).

thanks.