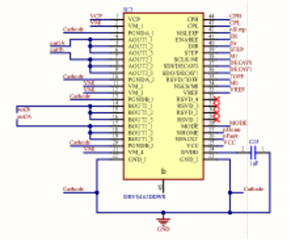

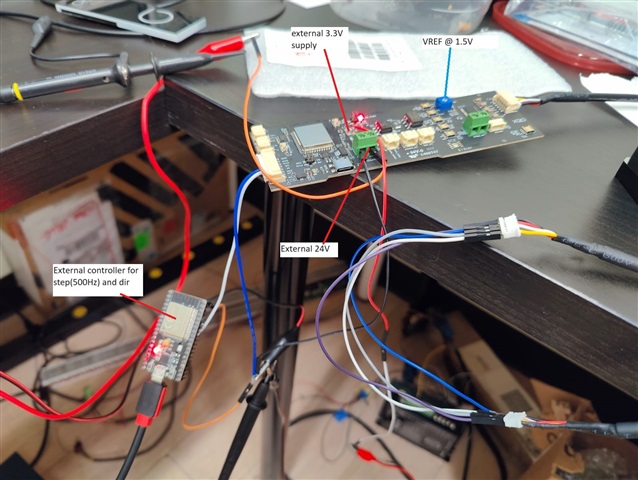

Other Parts Discussed in Thread: , LM1085, DRV8461

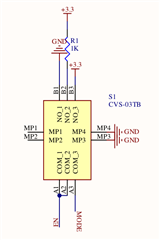

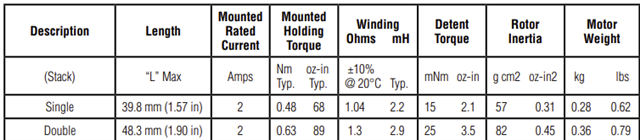

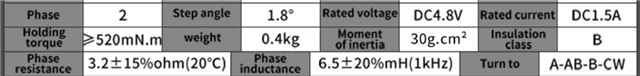

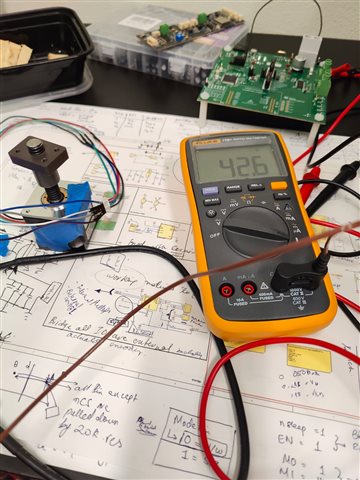

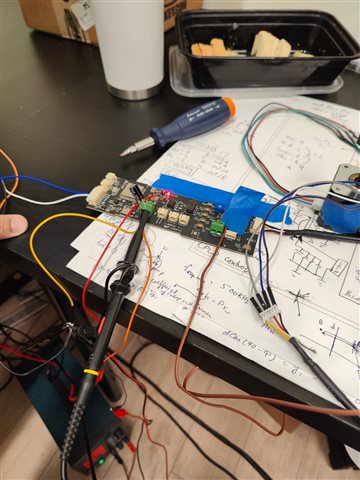

Hi I made A PCB with DRV8462, and I'm trying to control a stepper motor rated for 4A in manual mode.

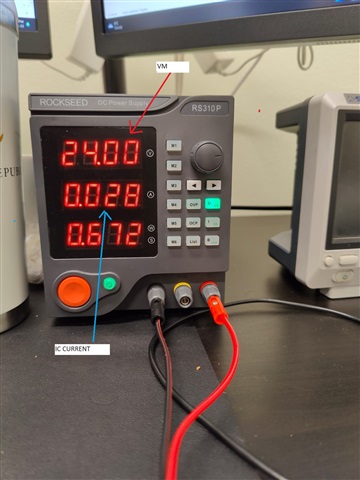

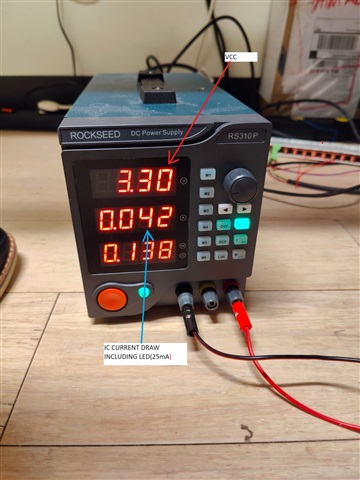

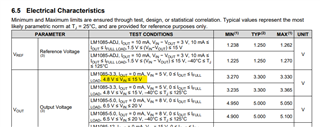

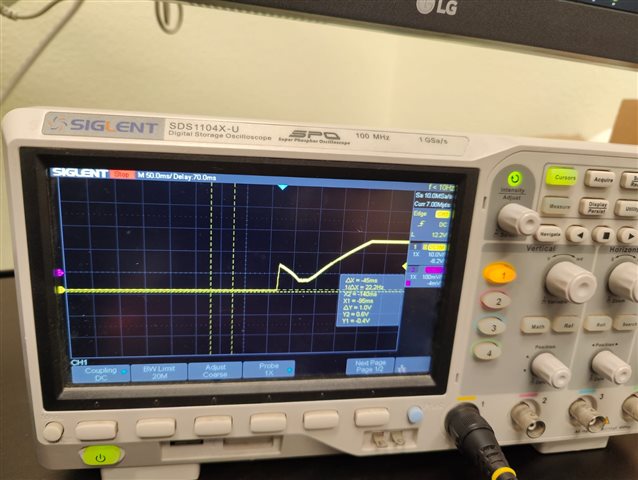

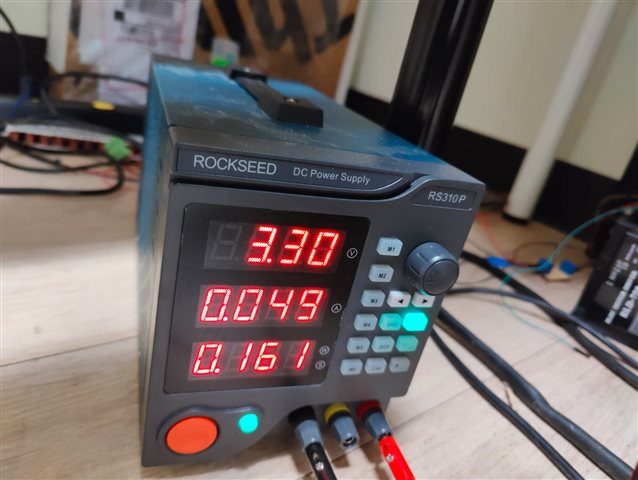

I tested the motor for 1/256 and 1/32 steps but motor wasnt responsive and drew alot of current as soon as i enable the driver, Although no step signal was given to the driver.

Then i tested the motor in full step 100% current and still the current was very high and after running for sometime the motor driver just shorted again.

I had 4 driver ICs, and my circuit is based on the application note in the data sheet.

The real problem is that the IC bridges keep shorting out as soon as i connected the motor.

The driver has a seperate layer(exposed on bottom) for heat dissipation and ground plane is not used on the IC back, the ground is given through the GND pins.

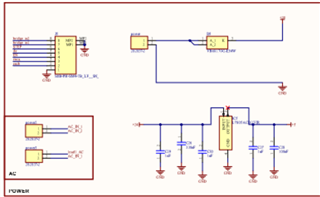

Bulk ceramic capacitors are added to the pcb, 100uF x4.