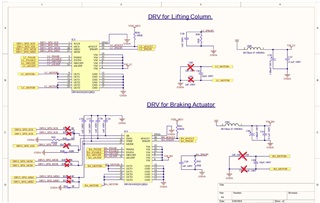

Other Parts Discussed in Thread: DRV8243H-Q1EVM

Hi experts,

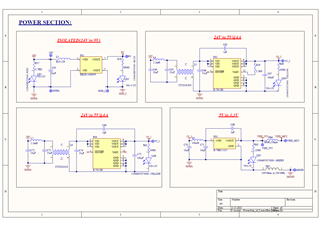

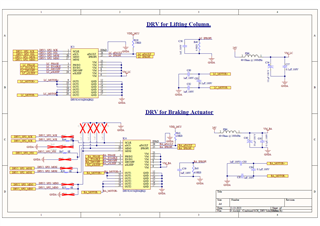

I am Anjali and this is my first hardware.

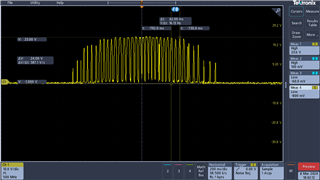

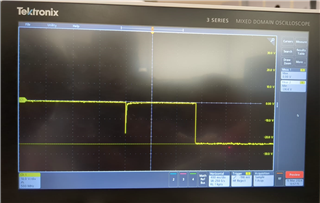

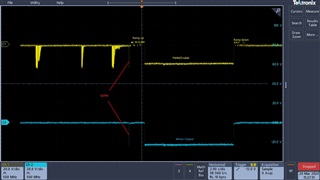

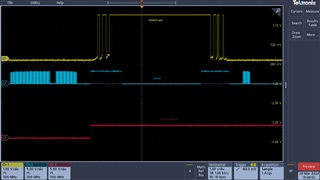

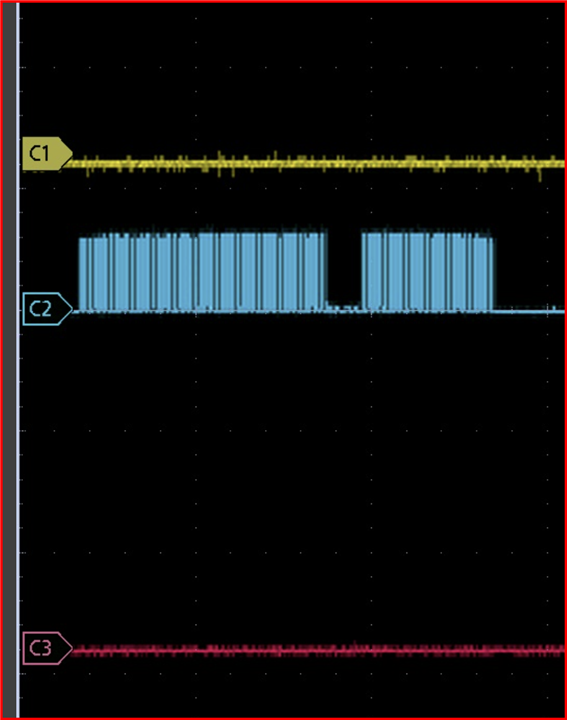

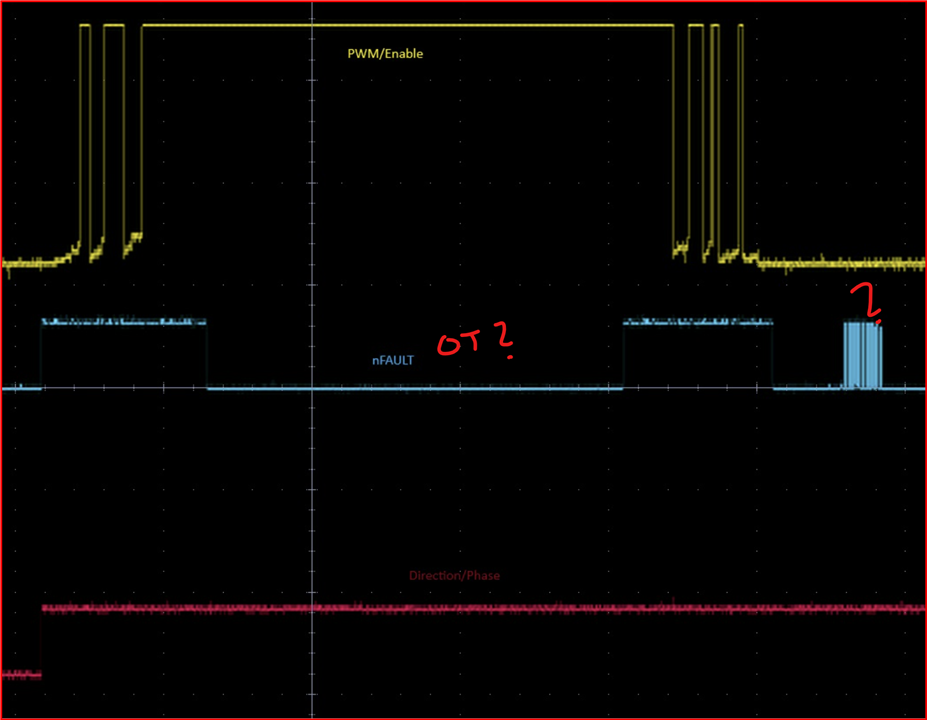

We are using the SPI version of the driver IC to drive the brushed DC motor of a lifting column. The maximum current taken by the bidirectional load is 2.2A. When testing with a different brushed DC motor (peak current drawn was 1.5A), the output was fine. However, when testing with the lifting column, the driver IC got damaged. The H-bridge is shorted causing a short between VM-GND-OUT1-OUT2. I am not able to deduce what caused the short since the driver is rated for much more than 2.2A.

Please share your insight on this. Thank-you!