Tool/software:

Hello Ti,

Greetings of the day!

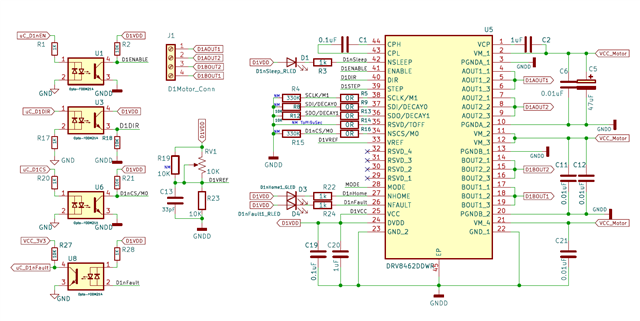

I designed a PCB to run Stepper Motor with DRV8462 Driver. Design Snap attached below.

I'm facing few major issues with it mentioned below:

- With Manual Hardware Interface :

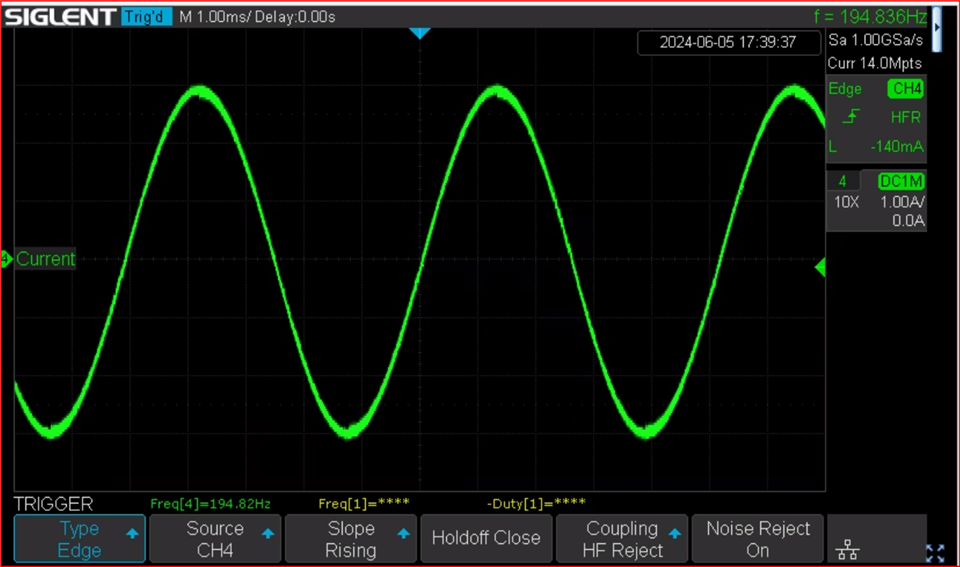

- Even with 100 kHz PWM on Step Pin, I'm not getting enough speed with this driver, micro stepping was set to 1/128(both mode pins left open). Also when I'm running motor for a while, it is getting heated up, and going into thermal shutdown.

- With SPI Interface :

- Steps are missing even on no load, motor is running with jerk, and also not getting enough speed. On startup it is demanding high current, even more than motor rated current, also heating in a while.

- Is there only way to set the STEP bit in CTRL2 Reg, to run the stepper motor only single step. Is it not possible to run the stepper by giving number of steps, and motor keeps running standalone until the step count ended up?

- Is there way to control the acceleration and deceleration?

I've tried almost every possibility I could understand from DRV8462's datasheet like, HW interface, In SPI Interface(stepping through SPI), Auto Micro-stepping, Auto torque, Decay Modes, Activating both rising and falling edge for stepping etc but could not achieve enough speed. I need to run the motor around 250 RPM, but currently it is running only around 25 RPM while the motor can run up to 1000 RPM as per its datasheet. Even we have run this motor up to 500 RPM with a driver module TB6600 without any issue.

I'm attaching Schematic snap and Code I'm working on. Please let me know if any further details are required and suggest the way forward.