Other Parts Discussed in Thread: DRV8210, DRV8212, DRV8210P, DRV8212P, DRV8801A-Q1, DRV8876-Q1, DRV8262

Tool/software:

Hello Expert,

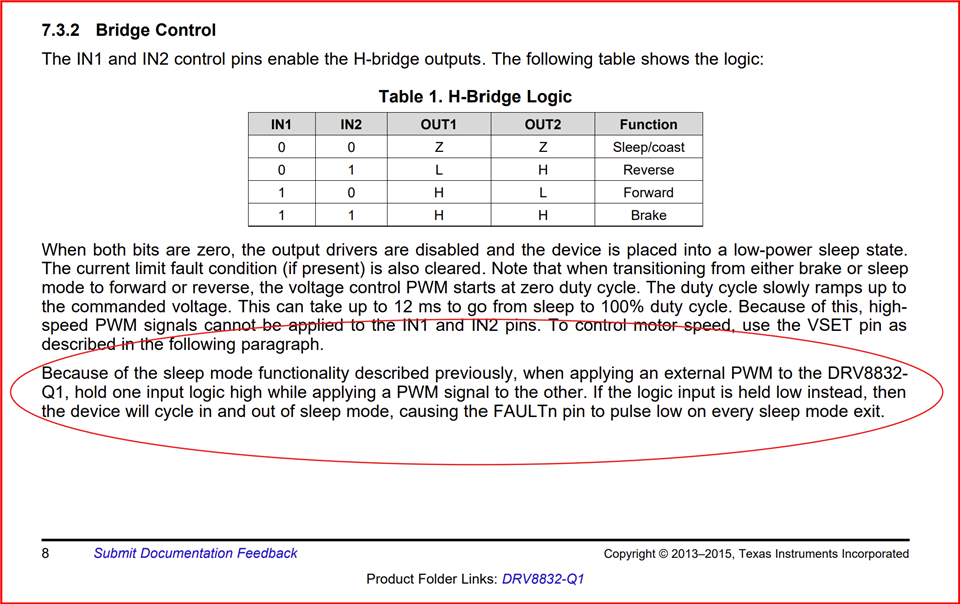

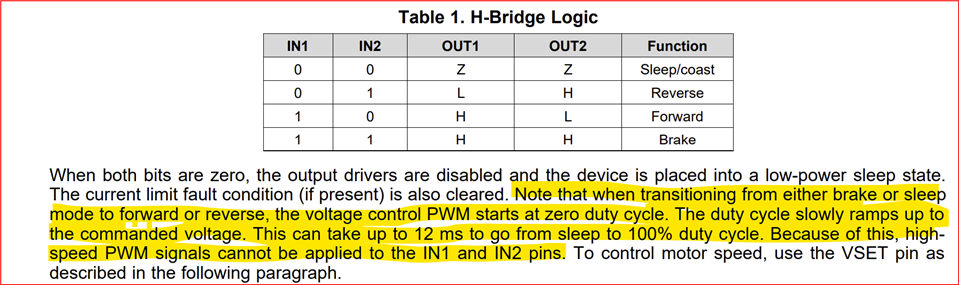

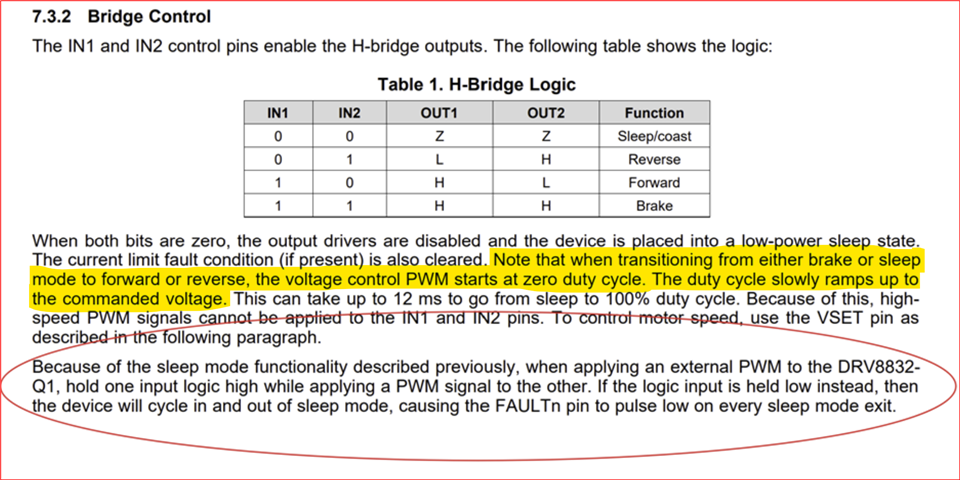

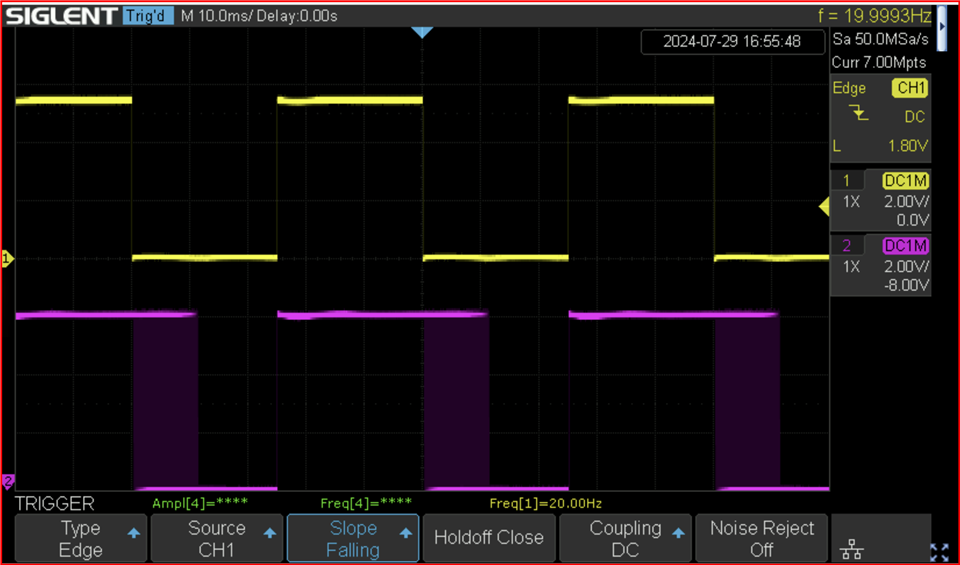

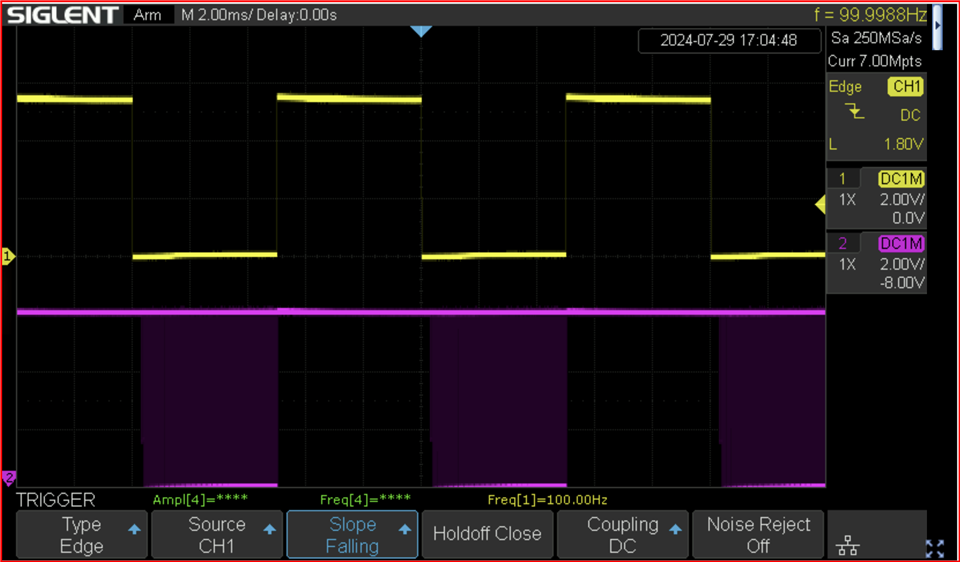

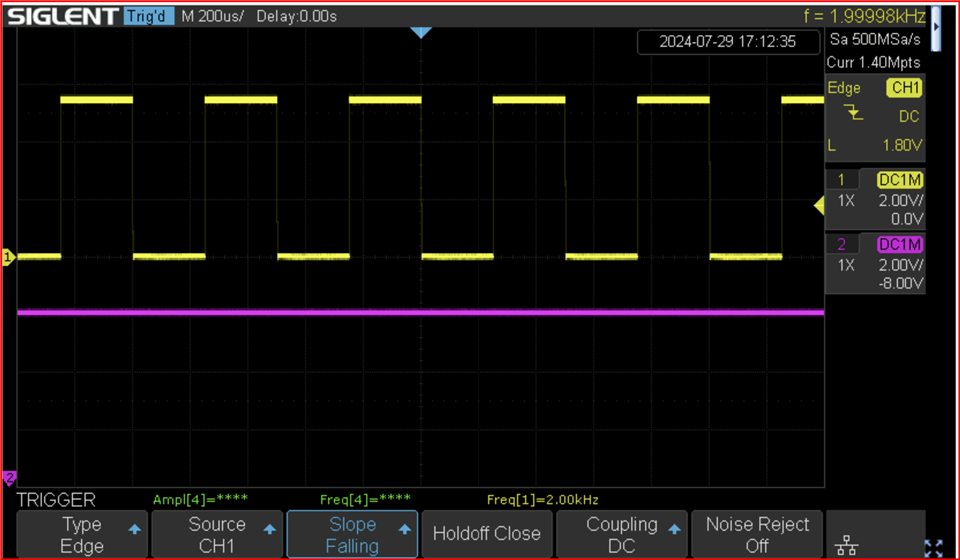

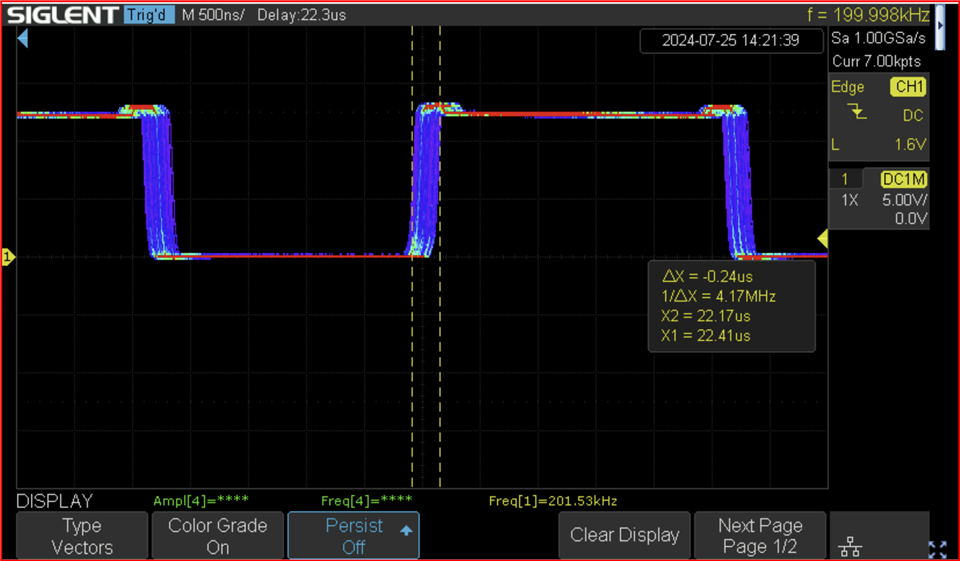

Could you please tell me maximum input frequency?

We are planning to use 20Hz to 20kHz signal.

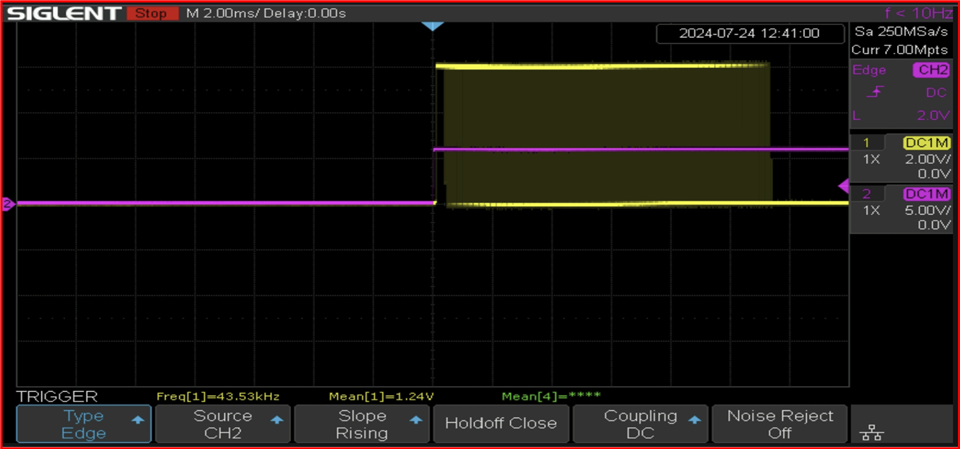

But voltage regulation Internal PWM frequency is 44.5kHz

So, I suppose the input signal frequency is limited and it is depends on Voltage regulation setting.

Best regards,

Kazuki Kuramochi