Tool/software:

Hello team,

Greeting for the day.

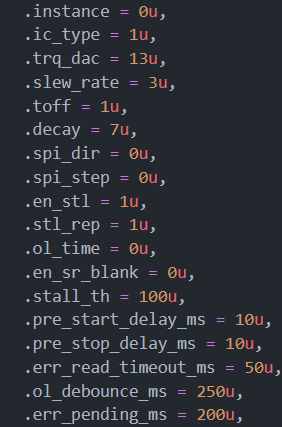

When TRQ_COUNT < STALL_TH, nFAULT is still high and STL bit is 0, attached file is the related registers. Can you help analyze the reason?

Thanks.

This thread has been locked.

If you have a related question, please click the "Ask a related question" button in the top right corner. The newly created question will be automatically linked to this question.

Tool/software:

Hello team,

Greeting for the day.

When TRQ_COUNT < STALL_TH, nFAULT is still high and STL bit is 0, attached file is the related registers. Can you help analyze the reason?

Thanks.

Hi Daniel,

The register configurations look like they are set up properly for stall detection.

What type of motor are you using (winding resistance, torque rating)?

What's the step rate?

Please see the following FAQ on some common issues that can cause unreliable stall detection:

Best,

David

Hello Medis,

Thanks for sharing.

Pls see the customer check result according to link:

Answer: I have configured it to ‘Smart Tune Ripple Control decay mode’, CTRL1 [bit0:2]=111b;

Answer: The motor coil resistance is about 8.2Ω. Stall threshold is 100;

Answer: Motor parameters are shown in here: PL35L-A24_zh.pdf (minebeamitsumi.com.cn), motor is same as TI document “Sensorless Stall Detection With the DRV8889-Q1”.

Answer:

Answer: I didn’t use stall learn mode, filled a const value(100) in CTRL6.

Answer: In general, 100 is bigger than TRQ_COUNT, at least in my case.

Answer: Yes, I manually set it.

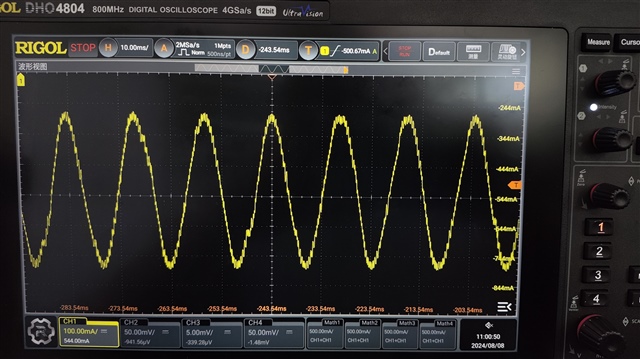

Answer: VM is 13V, coil current is 500mA, wave is as picture.

Can you help share your insights for the issue?

Hi Daniel,

The DRV8889-Q1 is known to work well with PL35L stepper actuator for stall detection and currently in production for headlight level control application for a while now. The stall threshold value of 100 mentioned by you seems a bit high.

Was it 1/16 uSteps? Did you also try 1/8 uSteps setting? What was the torque count with no stall and count during stall, what was the PPS step input? Thank you.

Regards, Murugavel

Hello Murugavel,

Now it is 1/8 step. TRQ_Count is about 100-120 without stall, 0-10 with stall. PPS I am not sure, I can show you my config:

Thanks!

Hi Daniel,

In this scenario a stall threshold of 40 to 50 should be able to detect a stall condition consistently. Thanks.

Regards, Murugavel