Hello,

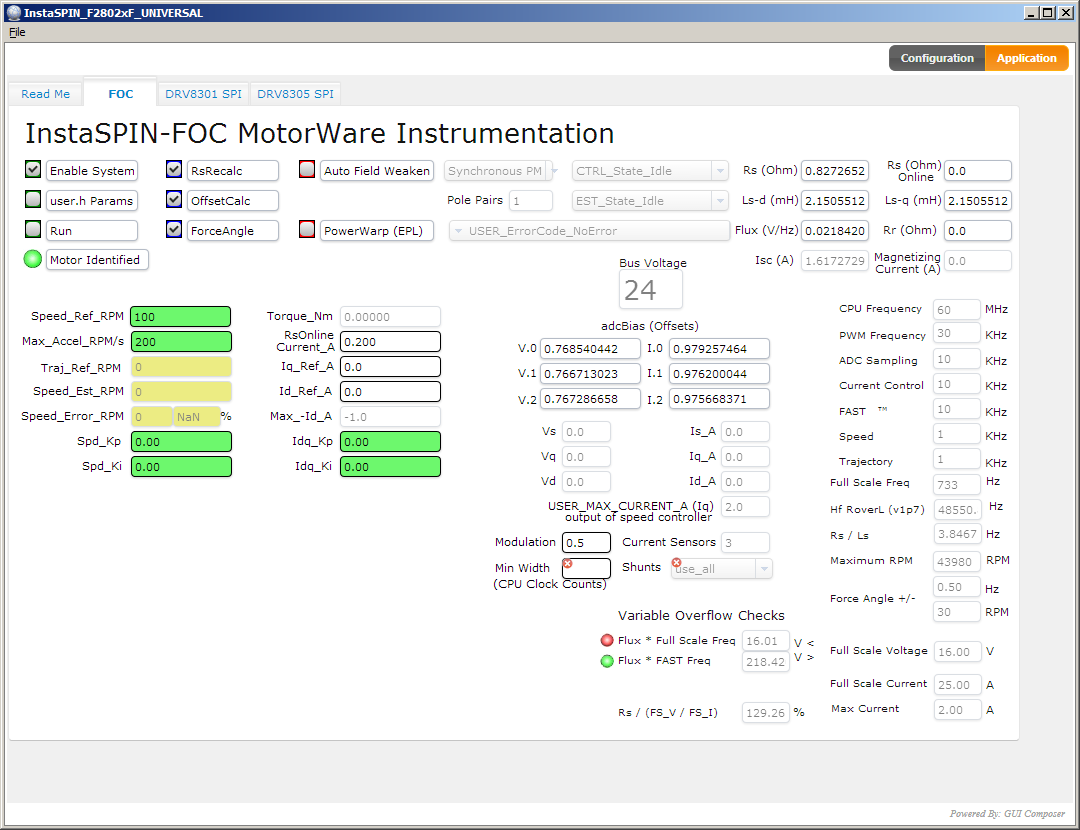

we try to run a small sensor-less BLDC motor (datasheet attached). We started as recommended with the toolchain: - Motorware.exe -> InstaSPIN-FOC -> Piccolo F2802xF -> GUI -> Universal GUI QSG (PDF) - Code Composer Studio with proj_lab02lc and edit the user.h file - InstaSPIN_UNIVERSAL.exe, using the appProgram.out file generated from proj_lab02c - hardware DRV8305 and Launchpad XL TMS320F28027F, 24V/16A power supply, motor EC1456

The toolchain works. But running the motor identification in InstaSPIN_UNIVERSAL.exe, we always get different results of Ls-d (mH). The results is any value between 0.0005 and 3.5 mH. The motor identification runs ok with all EST_States, also it speeds up to measure Flux and Ls-d. Sometimes it speeds up to 4000 RPM, sometimes it spins up to 4000, then 27,000. See screenshot attached. But after motor identification, the motor runs sometimes or not. Sometimes we get heavy shaking of the motor at RPMs from 10,000 to 30,000.

What we did to pre-initiialize the parameters in user.h: We use the recommended spreadsheet "docs\labs\ motorware_selecting_user_variables.xlsx" (screenshot attached). We have filled out the yellow fileds und 1. and 2. and the true-checks under 3. are green. Btw, how to continue with 4. and 4. and 5.?

We didn' t find a way to systematically move on with tuning the motor. Please give us advice how to proceed.

Best regards

Alois