Other Parts Discussed in Thread: MSP430FR2355, TIDA-00774, CSD88584Q5DC, TIDA-01516, DRV832X

Tool/software: Code Composer Studio

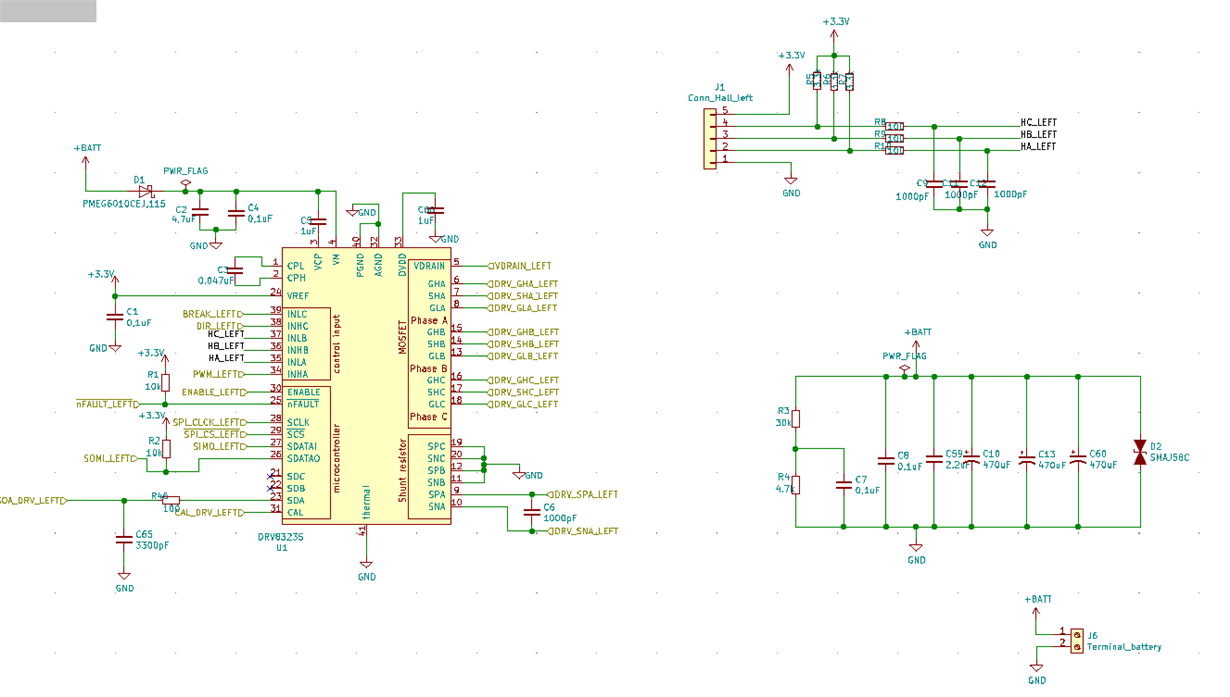

Hello, I'm using the DRV8323 to drive a brushless motor using sensored 1xPWM mode. I'm using MSP430FR2355 microcontroller to interface via SPI with the driver.

I'm using drv8323.h and drv8323.c from TIDA-00774 reference design to configure the driver, here is the code I use:

//DRV8323

P4DIR &= ~(BIT3); //Inputs - FAULT

P6DIR |= (BIT1); //Output - EN_GATE

P6DIR |= (BIT3); //Output - DIR

P6OUT |= BIT3;

P6DIR |= BIT4; //Output BREAK

P6OUT |= BIT4;

//code for DRV8323-SPI communication CS:P4.4, SCLK:P4.5, SDI:P4.6, SDO:P4.7

P4DIR |= BIT6; //GPIO-SDI

P4OUT &= ~BIT6; //Output-SDI

P4DIR &= ~BIT7; //Input SDO

P4DIR |= BIT5; //Output SCLK

P4OUT &= ~BIT5;

P4DIR |= BIT4; //Output nSCS

P4OUT |= BIT4;

P4DIR |= BIT2; //Output DRV_CAL

// code to enable the driver

P6OUT &= ~BIT1;

delay_us(150);

P6OUT |= BIT1;

delay_us(10); //10 us delay

//P4.2 DRV_CAL

P4OUT |= BIT1;

delay_us(150);

P4OUT &= ~BIT1;

delay_us(10); //10 us delay

//FAULT interrupt

P4IES |= BIT3;

P4IE |= BIT3;

P4IFG &= ~BIT3;

DRV8x_Analog_Init();

//Code for DRV8x_Analog_Init()

void DRV8x_Analog_Init(void)

{

SPI_Write(GATE_DRIVE_HS_REG, 0x03BF);

delay_1ms(1);

SPI_Write(GATE_DRIVE_HS_REG, 0x03BF);

delay_1ms(1);

SPI_Write(ADR_DRV_CTRL_REG, 0x0053);

delay_1ms(1);

SPI_Write(GATE_DRIVE_LS_REG, 0x06FF);

delay_1ms(1);

SPI_Write(OCP_CTRL_REG, 0x0160); //0x0160

delay_1ms(1);

SPI_Write(CSA_CTRL_REG, 0x0083); //0x0683

delay_1ms(1);

}

// code from drv8323.c

void SPI_Write(uint8_t address, uint16_t value)

{

uint8_t i;

uint16_t command = 0x0000;

address = address & 0x0F;

value &= 0x07FF;

command &= ~0x8000; //write command

command |= (address << 11U) + value; //set address and value

M1_SCLK_LOW;

__delay_cycles(15);

M1_nSCS_LOW;

__delay_cycles(15);

for (i=0; i<16; i++)

{

M1_SCLK_HIGH;

__delay_cycles(15);

if (((command >> (15 - i)) & 0x01) == 0x01)

{

M1_SDI_HIGH;

}

else

{

M1_SDI_LOW;

}

__delay_cycles(15);

M1_SCLK_LOW;

__delay_cycles(30);

}

M1_nSCS_HIGH;

__delay_cycles(15);

}

// some defines

#define M1_SCLK_HIGH (P4OUT |= BIT5)

#define M1_SCLK_LOW (P4OUT &= ~BIT5)

#define M1_SDI_HIGH (P4OUT |= BIT6)

#define M1_SDI_LOW (P4OUT &= ~BIT6)

#define M1_SDO_LEVEL ((P4IN &= BIT7)?(1):(0))

#define M1_nSCS_HIGH (P4OUT |= BIT4)

#define M1_nSCS_LOW (P4OUT &= ~BIT4)

I don't know if there's something wrong in the driver's configuration, I can't make it work. I attach schematics

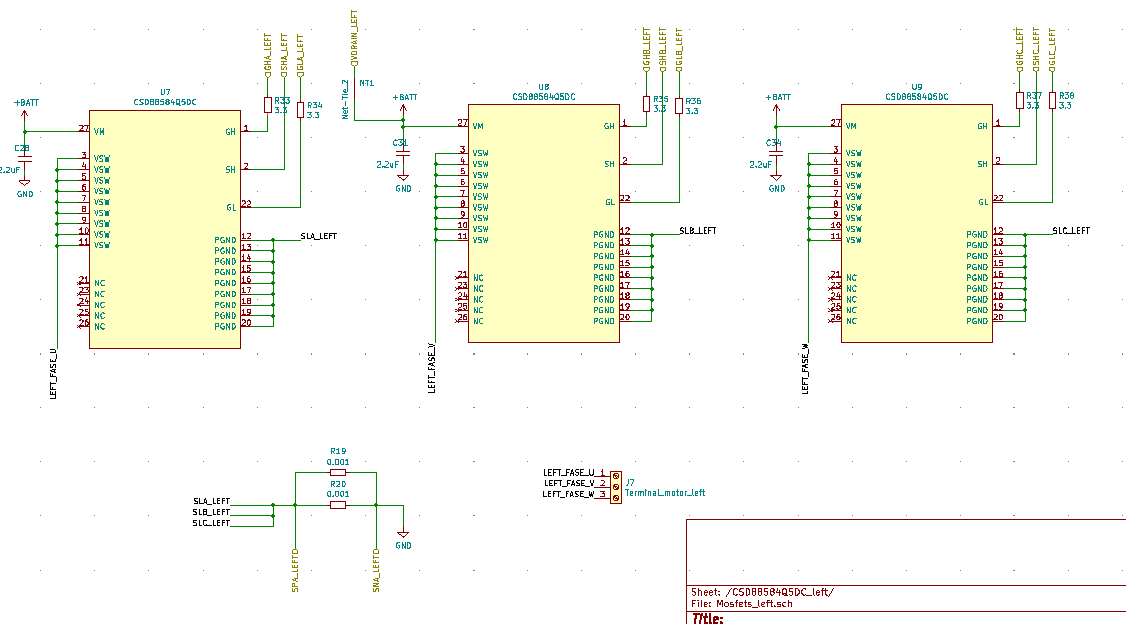

I'm using csd88584q5dc half-bridge power block,

I have the PWM signal in INHA pin, I see it with an oscilloscope, also the hall sensor inputs connected to the corresponding pins in schematic. I'm using 24V as VM.

I based my design on TIDA-00774 and TIDA-01516, I'm not an expert in the motor drivers field and I can realize there are lot of concepts and information I don't know,

Is the configuration I'm using ok? Any help would be really appreciated. Thanks in advance.

Diana