Other Parts Discussed in Thread: UCC3808-1, TL431

Hello,

I would appreciate if somebody could help me fixing a problem affecting an old design initially based on an UCC3808-1 and now using an UCC2808A-1.

Regards

Gilles

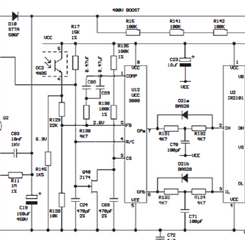

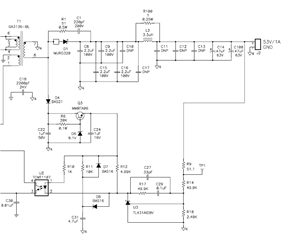

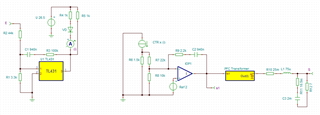

We are using an UCC3808-1 at 200kHz for a half bridge forward converter (400V to 35.8V 8A). See schematic in the attached pdf

WEFA339 H4 - FLAT.pdf

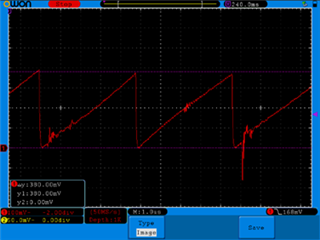

The ramp on the CS pin of the UCC3808-1 is not an actual image of the current but a ramp generated by an RC network.

We had problems keeping this ramp in range due to tolerances affecting the JFET Q40 and then opted to use the UCC2808A-1 which includes an internal FET for clearing the ramp on the CS pin.

The ramp is now in range [0 - 400mV] but some of the units do not start properly when running dry.

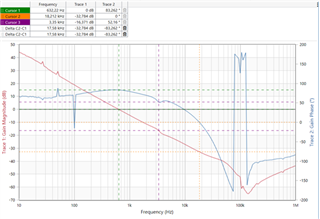

Are they any difference in the feedback between the UCC3808-1 and the UCC2808A-1 which could explain the problem?

Transformer:

primary: 20 + 20 turns ~1800uH

35.8V: 8, 8 turns

15V: 5 turns

26.5V: 6 turns

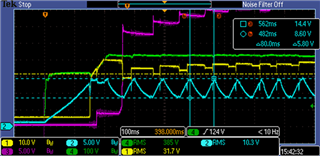

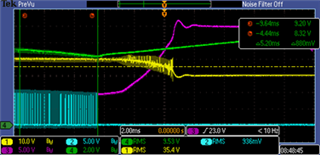

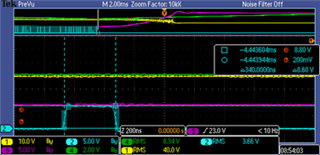

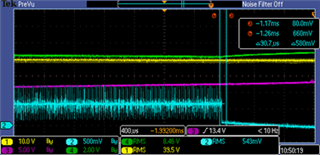

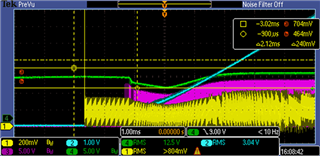

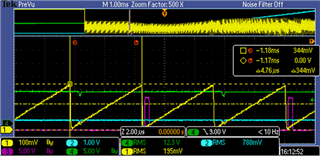

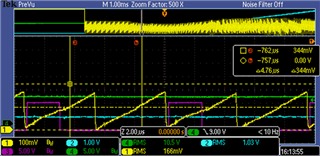

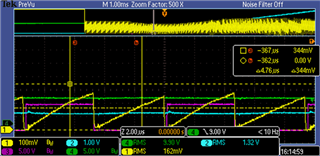

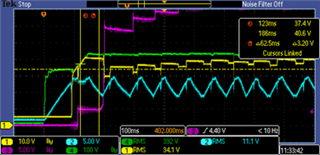

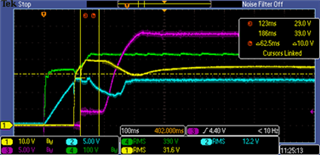

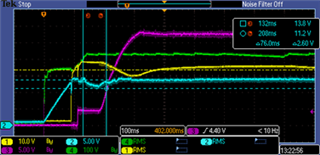

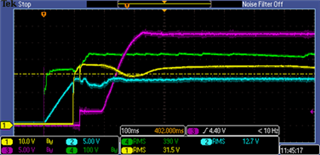

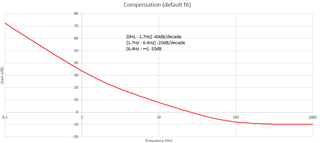

Below is scope capture and a sequence describing the problems:

1) Power-up "400V boost" (CH4) at ~340V

2) VCC (CH2) of the UCC2808A-1 (U12) reaches ~12.5V, the switching starts

3) the voltage on the 35.8V rail (CH1) increases and gets above the set point.

4) the duty cycle on the UCC2808A- 1 (U12) is too small to maintain VCC (CH2) above ~8.5V

5) the switching stops and the cycle restarts at step 2