Hi, TI expert.

There is an inquiry about the cause analysis of the failure that occurs during the development stage by applying the TPS22950 by the customer.

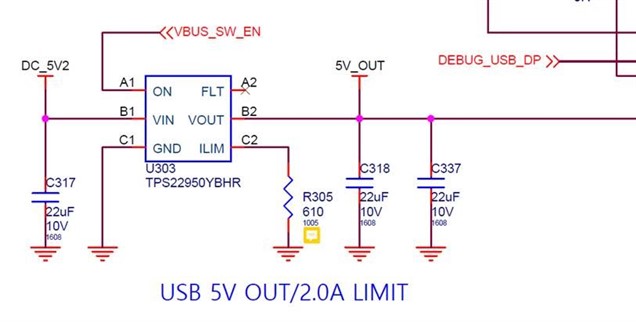

The circuit configuration is as above, and TPS22950 is enabled with 1.8V level input through A1 pin.

The side that goes out to the right through the B2 pin is connected with a USB type C connector.

In the product development stage using this device, the B1 and B2 pins of the TPS22950 failed due to a short circuit. (2ea out of 100ea, 2% chance)

In the broken sample, there was no current consumption enough to cause the TPS22950 to overheat, and only data communication was performed by connecting to a notebook PC through the USB C connector.

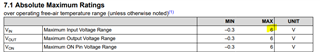

When the USB type A to C cable is connected to the laptop on the USB C connector side, there are cases where the laptop output 5V power is connected to the VOUT part of the TPS22950 device.

In this case, we would like to ask for your help in figuring out what factors may cause the TPS22950 to fail as above.