In order to improve efficiency and driving range, a major trend in electric vehicle is the increase of the battery voltage from 400V to 800V or higher. For the same reasons, 800V systems may also move from silicon-based IGBTs to silicon-carbide (SiC) MOSFETs for the power stage. Those changes will impact the challenges and choice of gate driver in high voltage HVAC applications such as HVAC AC Compressor and PTC Heater.

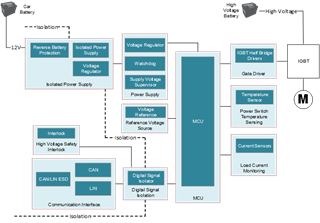

Before looking at the gate drivers’ requirements and solutions, let’s first have a look at the typical architecture seen in high voltage HVAC AC compressor applications. In order to have a platform approach as well as to keep the solution cost effective, an architecture with isolated communication, as shown below, is the most often used.

Figure 1 High voltage compressor with isolated communication architecture

The change in voltage as well as of transistors leads to two main changes at the gate driver level. The first one is the need to support a voltage greater than the 700V max of the traditional non-isolated half bridge driver, so one would use an isolated gate driver to support the higher voltage. The second is the inclusion of features to adequately drive IGBT or SiC transistors.

The table below lists some useful features and why they are of interest for both IGBT and SiC transistors:

|

Feature |

Why it matters |

|

Split outputs |

· Reduce bill of material and space · Help prevent false turn on |

|

Programmable dead time |

· Prevent shoot through · Small dead time improve efficiency |

|

Small propagation delay and delay matching |

· Help to reduce dead time and improve efficiency |

|

Under voltage lock out (UVLO) |

· Higher UVLO threshold limits conduction loss |

|

Miller clamp |

· Help prevent false turn on of low-side power switch |

|

Desaturation protection (DESAT) |

· Prevent desaturation operation of the power switch that results in overheating |

|

Interlock protection |

· Prevent high-side and low-side power switches to be turned on simultaneously |

See this application note for more details

What gate driver solutions can be considered for battery voltages <700V?

In HVAC AC compressor applications where the voltage rating is below 700V, a half bridge gate driver, such as the UCC27712-Q1 would be ideal as it includes some useful features such as interlock and deadtime function.

What gate driver solutions can be considered for battery voltages >700V?

For a battery voltage higher than 700V, as traditional non isolated half bridge driver can only support 700V maximum voltage rating, both Compressors and PTC Heaters would require functional isolation on the gate driver side to withstand the voltage . The two possible architectures are:

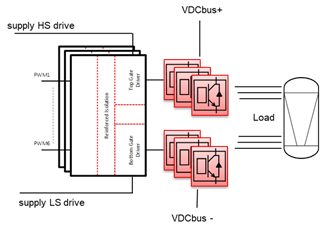

- One chip solution with dual-channel isolated gate driver for each motor phase – both high-side and low-side power stages of each phase are driven by isolated gate drivers, thus requiring 3 dual channel devices

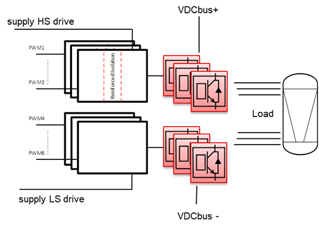

- Two chip solution with a single-channel isolated driver for the high side and a single channel driver, either isolated or non-isolated for the low side.

Figure 2 Dual-channel isolated gate driver

A dual channel gate driver presents several advantages including built-in programmable dead time, better channel-to-channel matching and smaller board size compared to a two chip solution. The UCC21530-Q1 would be a good example of a dual-channel isolated gate driver for high voltage compressors.

Figure 3 Isolated high side driver / non-isolated low side driver

Using a two single-channel gate driver solution offers more flexibility, allowing to place the driver closer to the transistor, thus optimizing the gate drive loop, as well as naturally increasing the channel-to-channel spacing required in high voltage application without necessarily needing conformal coating. Using a non-isolated gate driver on the low side could help to reduce the solution cost. A combination of the UCC5350-Q1 for the high side and the UCC27624-Q1 for the low side would be a good solution for high voltage compressors or PTC heaters.