Dear TI Engineers.

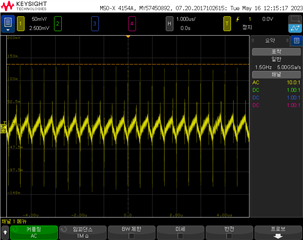

I have some issues about EMI(CE) Noise & Ripple.

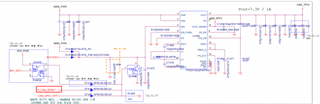

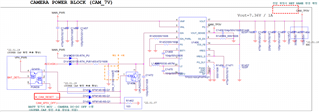

1. Issue: EMC (CE) Fail due to Ripple & Noise in the output of TPS55160QPWPRQ1 being used as CAMERA POWER.

- 100Mhz Band Fail (10db over)

2. Low-frequency noise is reduced by applying a lower inductance component

- Inductor. Spec : 3.3 ~ 6.2uH

- Currently applied value: 4.7uH [EMC Fail]

- Value applied after debugging: 1.5uH [EMC Pass]

3. Additional debugging

- No change in Ripple & Noise even when a 4.7uH inductor with a low DCR value and a large current capacity is applied.

4. Inquiries

- Ask if 1.5uH lower than the Min. value of 3.3uH is available.

- Inquire about additional ways to output clean power.

Thanks.