Hi expert,

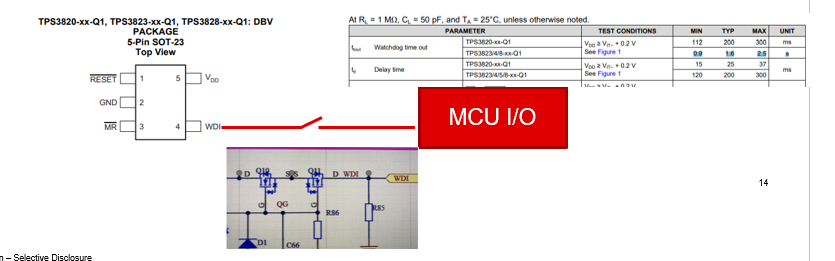

TPS3823-Q1WDI working modes:

- Use: external I/O

- Unused:

- Floating (high impedance): internal timer

- Place a 1-kΩ resistor from WDI to ground: need BU to explain the working mechanism ( What is the operating mode that is not in high impedance? )

Application description:

- Customers have special functional requirements when using TPS3823. There is a switch between MCU and WDI for control.

- It is expected that when the switch is on, the external WDI signal is given. When the switch is off, the external WDI signal is stopped and the internal WDI signal is used.

Support Needs:

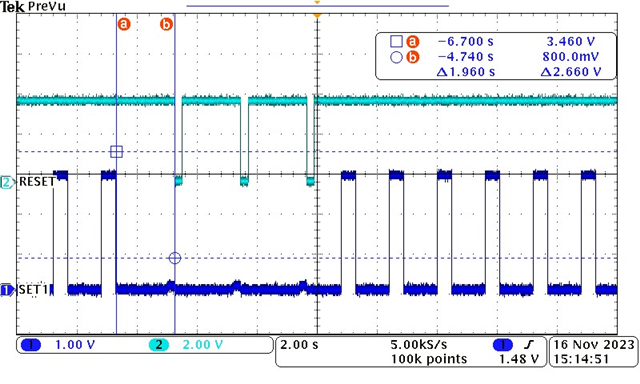

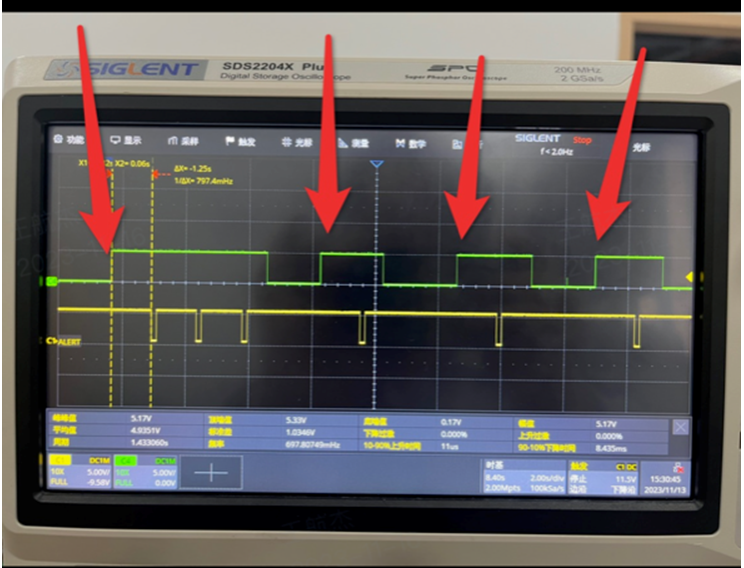

1. Need your help to explain whether the internal timer will start counting from 0 again with a delay when the TPS3823 switches from the high-impedance state to the I/O port.

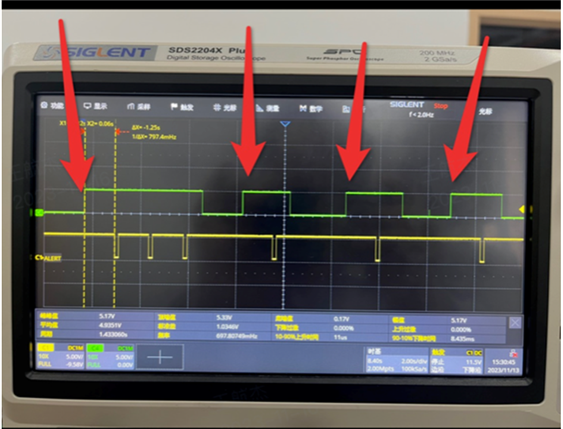

2. The customer did some tests, closed the switch, switched the WDI from high impedance to I/O( the I/O port did not send a signal ), and found that the time from switch conduction to MCU reset is 180ms~600ms

3. How does the WDI pin determine that it is in a high resistance state?

4. What is the threshold of high resistance state resistance? Or how much more than the resistance value between the WDI foot and the ground will be determined as a high resistance state?