Other Parts Discussed in Thread: TPS65987, TIDA-050012, TIDA-050014, TPS65987DDJ, TPS65987D, TPS65981, TPS65987DDK

Hello,

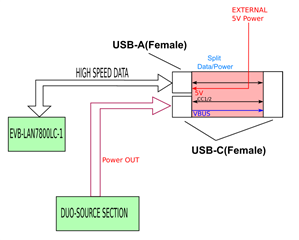

I'm trying to use the USB-C-PD-DUO-EVM by following the USB-C-PD-DUO-EVM User's Guide,

but I'm noticing that there are differences between the SW release date

"

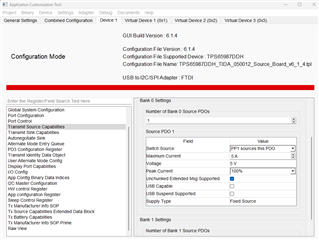

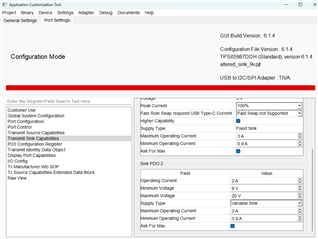

TPS65981_2_7_8 Application Customization Tool

GUI Version: 6.1.4

Release date: March 29, 2023

"

and the date of the manual

"SLVUBJ5–October 2018".

Q1 - Would it be possible to have a version of the manual aligned with the SW release date?

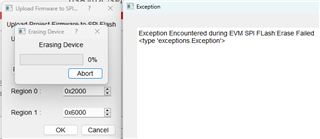

In any case I'm trying to take the first steps, but I'm having a lot of problems.

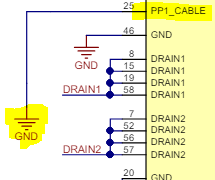

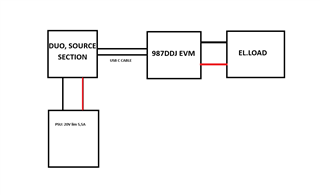

My HW is this: J1 powered with 19,5V, PC connected with a usb micro cable to the EVM.

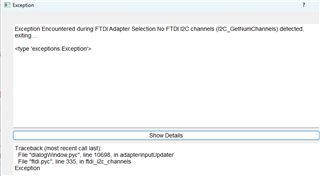

As for the interface connection, I believe this is there, in fact with the usb micro disconnected

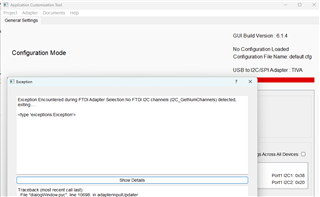

I get this message

"Exception Encountered during FTDI Adapter Selection:No FTDI I2C channels (I2C_GetNumChannels) detected, exiting....

<type 'exceptions.Exception'>

"

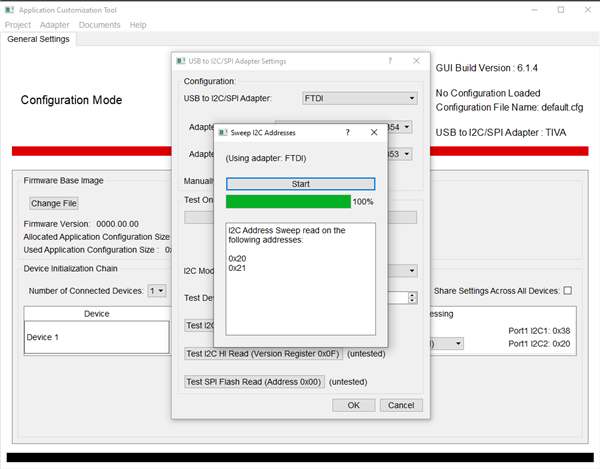

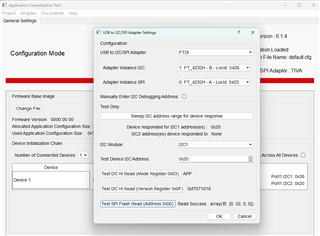

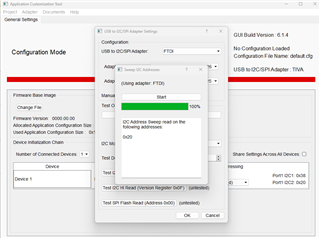

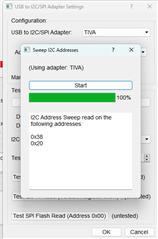

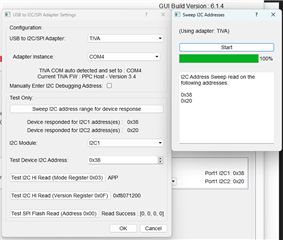

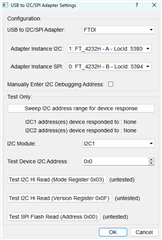

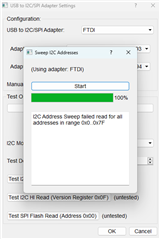

while when the micro usb cable is connected I get this popup when I click on "adapter"

but if I perform the Sweep I2C Addresses it fails

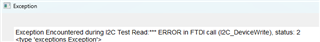

then if I try "TEST I2C HI READ (MODE REGISTER 0x03)

I get this FAIL MESSAGE

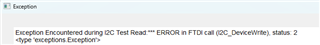

then if I try "TEST I2C HI READ (MODE REGISTER 0x0F)

I get this FAIL MESSAGE

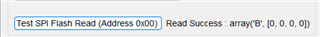

then if I try "TEST SPI FLASH READ (Address 0x00)

I get this SUCCESS MESSAGE

Q2 - how can I fix the problem (if any) with I2C?

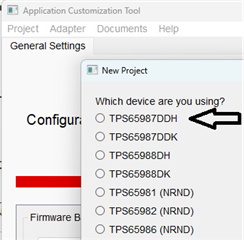

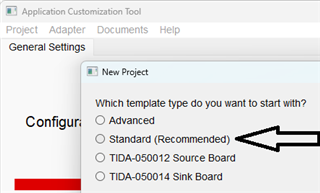

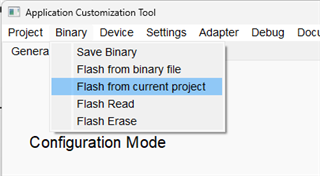

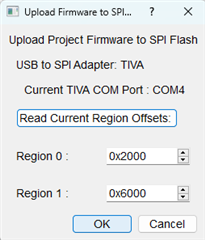

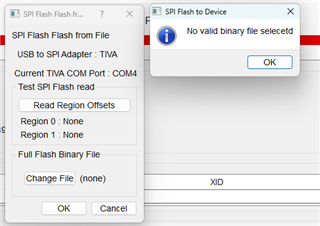

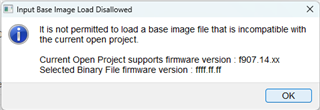

Q3 - which is the file to be loaded, that I cannot find source.bin or sink.bin?

Q4 - when loaded a .bin file wuth "change file" button, which is the command to start flash?

Thanks

Alessandro