Other Parts Discussed in Thread: BQSTUDIO, BQ34Z100EVM, EV2400, BQ34Z100, GPCCHEM

Hi, TI expert.

A customer is reviewing the BQ34Z100-G1 and has a question.

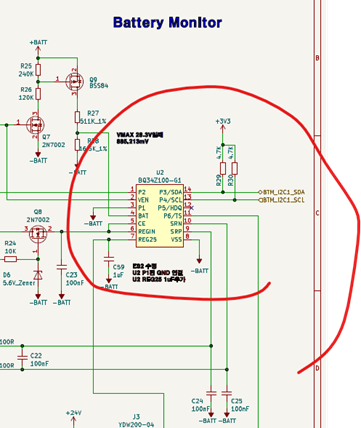

- Application: Tracker Control Unit (TCU), which controls the motor that moves the solar panel, for use after charging the battery using solar energy

Since this is the customer's first time using Fuel Gauge, there are a lot of things they don't know, so they have a lot of questions. Can you help them?

[Customer Inquiry details]

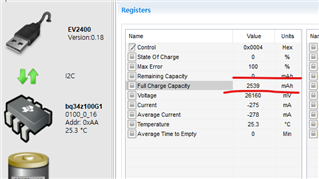

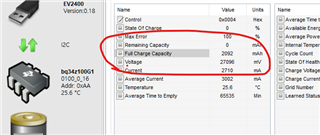

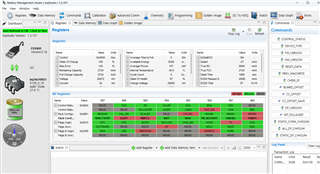

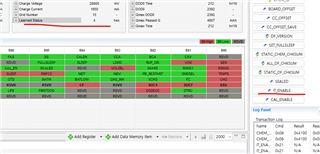

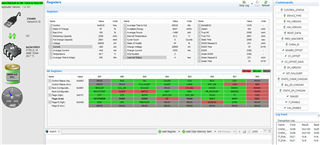

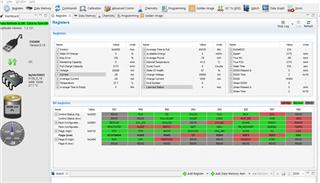

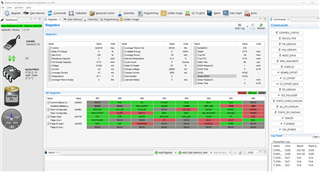

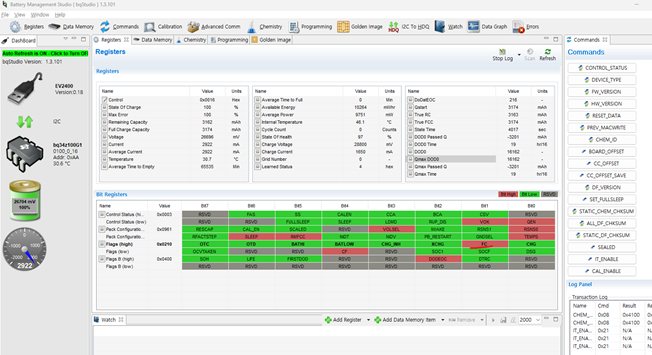

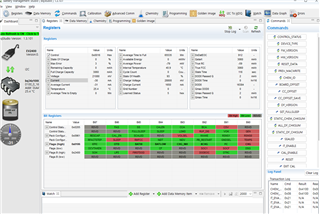

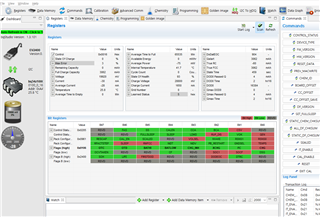

It appears that there is a method for extracting/programming images with Bqstudio using BQ34Z100EVM and EV2400, but I am not sure after checking the document, so I am asking a question.

1. If you look at the slyp822 document, it appears that it shows how to program using 12 EVM boards during the mass production process. (https://www.ti.com/lit/ml/slyp822/slyp822.pdf?ts=1709625254650&ref_url=https%253A%252F%252Fwww.bing.com%252F)

2. If you look at the slua801 document, it appears that it shows how to program in the case of a single cell. (https://www.ti.com/lit/an/slua801/slua801.pdf?ts=1709701538855&ref_url=https%253A%252F%252Fwww.ti.com%252Fsitesearch%252Fen-us%252Fdocs%252Funiversalsearch.tsp%253FlangPref%253Den-US%2526searchTerm%253Dslua801%2526nr%253D309)

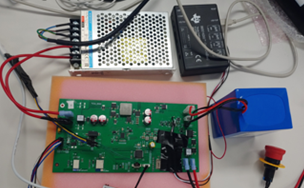

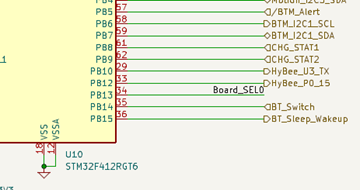

The Tracker Control Unit (TCU) board under review is connected to the BQ34Z100-G1 via I2C bus, with an MCU (STM32F412_Stmicro).

There are no connectors or other components for connecting to bqstudio in between.

I don't think I will be able to use bqstudio because mass production is required for official mass production.

The part you want to check is when mass producing the Tracker Control Unit (TCU) board.

I am curious about how to program the Golden Image of BQ34Z100-G1.

1. When purchasing BQ34Z100-G1, do I need to program the golden image in advance and assemble it?

2. After assembling the PCB, is it possible to write a code to program the golden image using I2C during mass production?

3. Do I need to create a download connector for BQ34Z100-G1 on the PCB, disconnect the MCU, and program it?

I am still thinking about whether I may need to modify the circuit according to this information.

I'm still looking at the document, but I'm not sure.

Please check. Thank you.