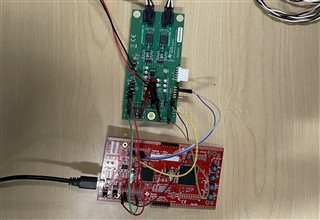

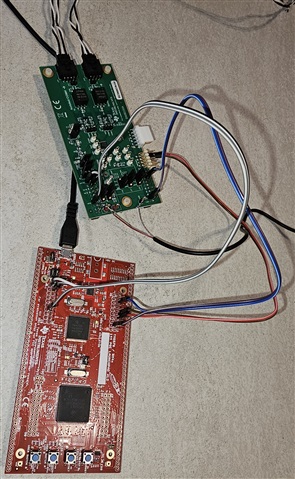

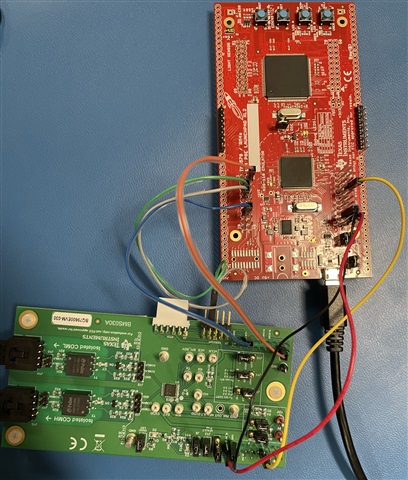

Other Parts Discussed in Thread: LAUNCHXL2-TMS57012, BQ79616EVM-021, BQ79600EVM, HALCOGEN, USB2ANY

Hello,

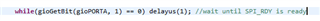

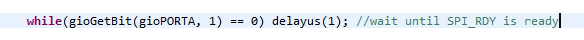

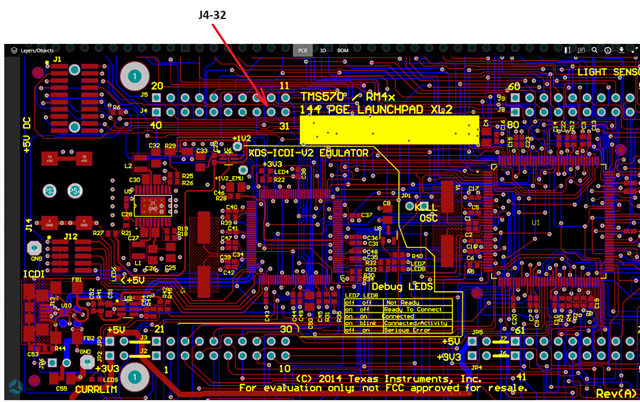

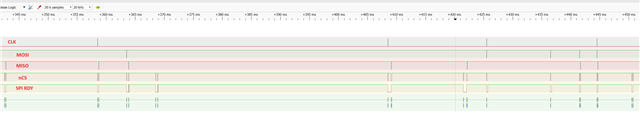

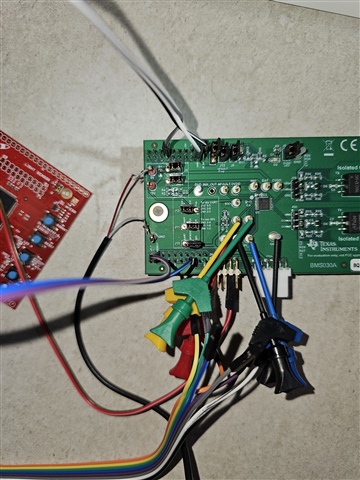

I use a TI example project for spi communication between TMS570 and BQ79600.

And trying to read out the voltage values.

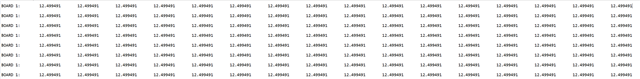

But the values whitch I get back are much to high and same fo every channel.

Could you please take a look into the project and help to solve the problem.

Thank you in advance

Harry