Other Parts Discussed in Thread: BQ27427, BQ25302

Hello Team,

We are currently developing a wearable device, and I would like to request your review of the power section schematic of our system to ensure everything is correct.

Description:

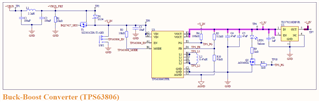

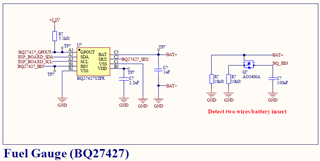

The system features two power sources. The first is a USB Type-C (5V3A max expected) for charging and sustaining backend system operations. The second source is a 3000 mAh 4.2 V Li-Po battery. Both power sources are integrated into the VIN of TPS63806 through a load sharing circuit consisting of a PMOS SI2301CDS-T1-GE3 and a Schottky diode SS34.

Selected ICs:

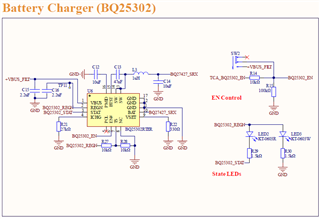

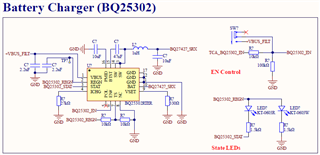

- Battery Charger: BQ25302RTER

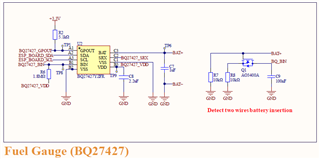

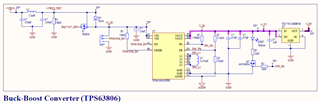

- Fuel Gauge: BQ27427YZFR

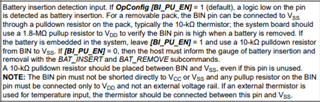

- Buck-Boost Converter: TPS63806YFFR

Screenshot:

Additional Questions:

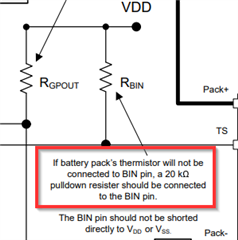

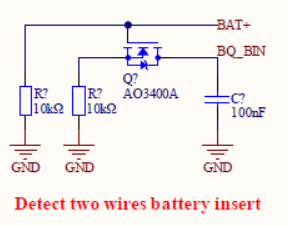

1. The BIN of BQ27427 requires a pull-up resistor(1.8 MΩ, As R6 in sch) connected to VDD (1.8 V). Since our battery setup does not include a thermistor, there is no pull-down resistor. Therefore, we designed an NMOS to simulate a ground resistor on the battery (refer to "Detect two wires battery insertion"). Is this design approach reasonable?

2. As I understand, when the battery is removed, the BQ25302 should not output any voltage, even though the device is enabled. Consequently, the LDO of BQ27427 cannot receive any power, implying that the I2C should not be operable. If maintaining the I2C connection for the BQ25302 is not feasible, is the circuit mentioned in question 1 necessary? Or can I determine the absence of the battery using an I2C timeout? Additionally, do you have any suggestions on how to keep the I2C of BQ25302 operational when the battery is removed but VBUS is present?

3. During normal operating modes, the anticipated supply current is < 0.7 A. Given that the wearable device also includes some PZT actuators, there might be current spikes lasting a few milliseconds (≤ 2.5 A). Is the system viable under these conditions?

Attache are the schematics for the power section, as well as those including the USB and microcontroller. I appreciate any feedback and thank you once again for your assistance.

Best regards,

Dennis