- Ask a related questionWhat is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.

This thread has been locked.

If you have a related question, please click the "Ask a related question" button in the top right corner. The newly created question will be automatically linked to this question.

Dear all,

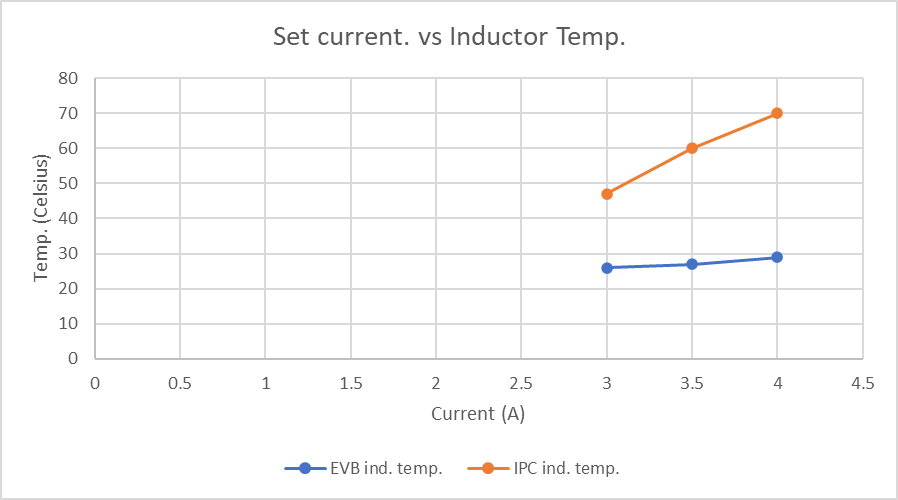

I have incorporated an LMR51450 into my design for a 2 layer, 1 oz PCB. I tried to follow the guidelines in section 9.5.1 of the datasheet. The regulator works well and I have tested it up to 2 A with sucess and up to 4 A with partial sucess (regulator works but temperatures become quite toasty).

I am attaching a graph of the results for current vs. temperature (this is the temperature measured with a laser temp. gun, so take it only as a reference). The blue line shows the temperature of the inductor in the LMR51450 TI EVB. The orange graph shows the temperature of the inductor in my PCB.

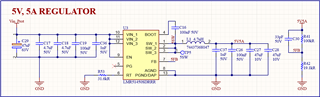

The schematic follows:

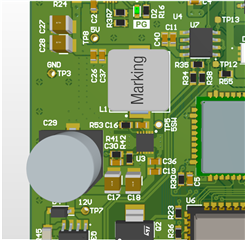

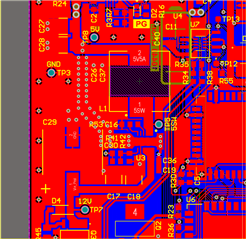

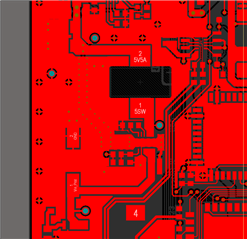

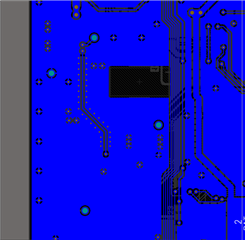

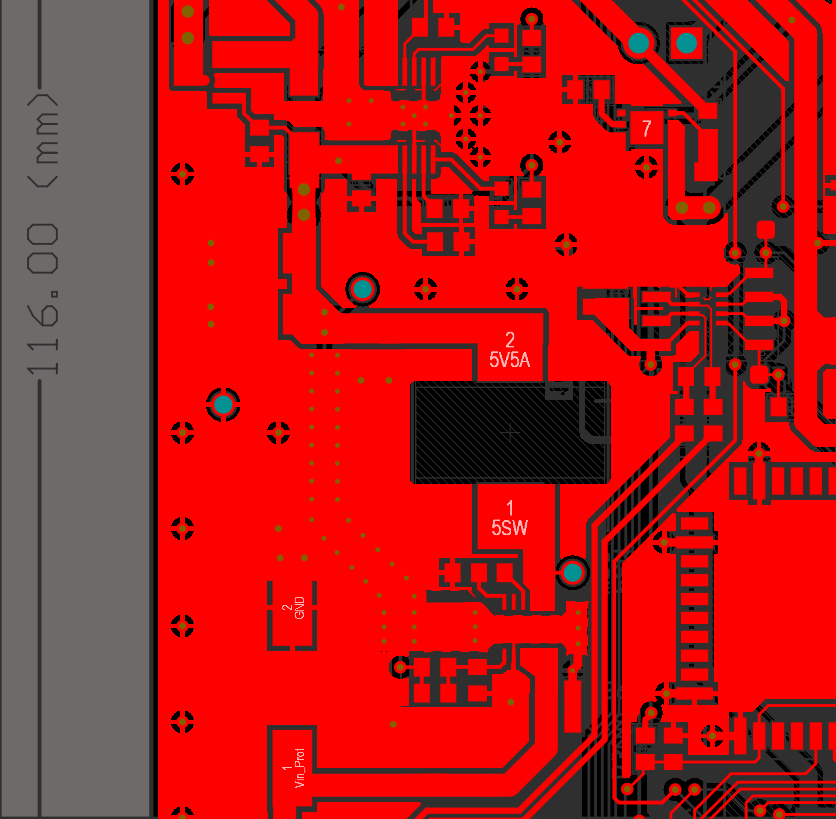

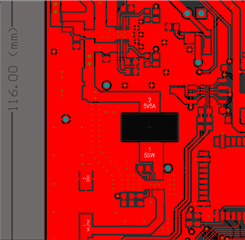

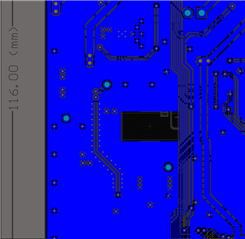

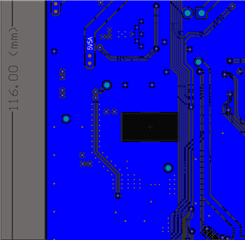

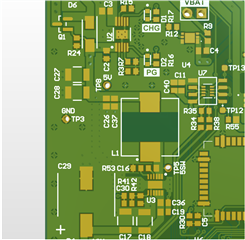

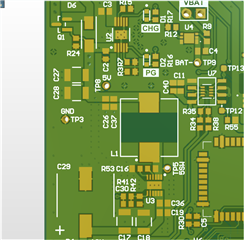

I am also attaching pictures of the layout.

|

|

|

|

Would you be so kind as to give me some pointers as to what can be improved? I was thinking of moving to a 2 oz copper PCB. Could this help? Changing to a 4-layer PCB at the moment would be quite unfeasable.

Best,

Dan

Hi Dan,

Thank you for your question and sharing your layout. In terms of your layout there are a couple things I noticed that might help in terms of thermal performance:

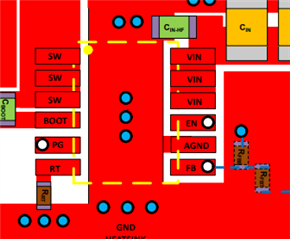

1. There should be vias underneath the IC to connect the ground of the device with the ground plane beneath it. These vias can aid by adding more immediate paths for heat to exit the board. See the diagram below for reference:

2. If the temperature of your inductor specifically is heating up, it may be that the inductor is saturating at higher current. Can you please share the part number of the inductor?

3. The thermal reliefs on the vias of your board will contribute to a reduced ability to relieve heat. Please consider direct connections from the ground planes on the top and bottom layers to their associated vias ensure maximum heat dissipation.

In terms of your PCB, moving to a 2 oz copper board should help with thermal dissipation. The TI board is a 4 layer board, so I imagine a 2 layer board would have reduced thermal dissipation capabilities, but these small changes can help with thermal performance.

Thank you,

Joshua Austria

Dear Joshua, Thank you for your prompt reply and suggestions. I will attempt to follow them and get back to you on results when the new PCB is fabricated. I used the same inductor as in the TI EVB (namely Wurth Electronics Cat. No. 74437368047). Note that it is not only the inductor that is getting hot in my PCB, but the whole area surrounding the regulator. I just used the inductor temperature as a proxy.

Best,

Dan

Dear Joshua,

I have now updated the layout. Before sending for fabrication I wanted to see if you had any additional input. Below I am attaching some pictures of the original (left) and updated (right) layouts. Note the main changes were:

I appreciate your input.

| Original | Updated |

|

|

|

|

|

|

Hi Alvarez,

Thank you for your update. I agree with all these changes and hope that this will improve thermal performance.

I do have to ask however what the reasons are for the remaining thermal reliefs on the vias, especially those on the bottom ground plane (but also some at the top of the ground path from the IC). I would recommend removing the thermal reliefs on the remaining ground vias to maximize thermal dissipation unless these thermal vias are critical in the design. If these thermal reliefs are important in the design, then I do not have any other recommendations.

Thank you,

Joshua Austria