- Ask a related questionWhat is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.

This thread has been locked.

If you have a related question, please click the "Ask a related question" button in the top right corner. The newly created question will be automatically linked to this question.

Hello,

We need help here to solve RE testing failure issue.

Please see attached docs.

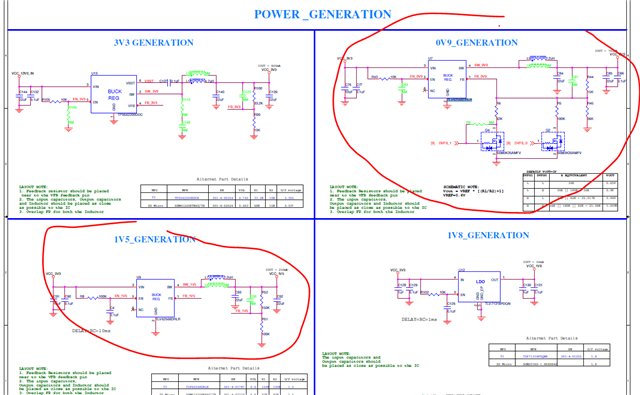

3.3V Generation Camera Supply uSD card board

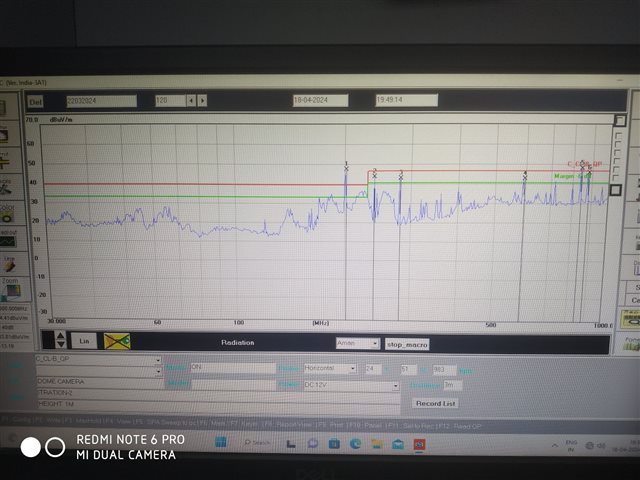

Before 3.3V Ouput HW modifications

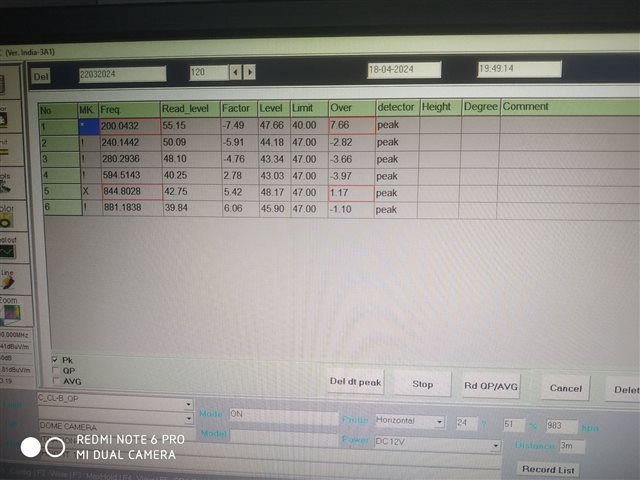

After 3.3V output HW modifications

Hi Brijesh,

Have you try changing the RC snubber value? You can measure the SW node voltage and adjust the Rsnub and Csnub to get a lowest SW spike. And the inductor direction can also affect RE. You can try to rotate the inductor8 to see if any improvement.

Best Regards,

Shipeng

Hi Shipeng,

We have measured SW node Voltage and calculated RC snubber values from calculation we are getting R=4E and C=0.2uF so we have used this values and tested again. we see little bit good improvements but still it is not passing. We checked inductor polarity as well so there is no polarity in the inductor we have used.

Please see results with R=4E and C=0.2uF snubber values and suggest us better way to pass RE. We are really stuck and need to solve this issue in a very hard time limit.

Hi Brijesh,

Sorry I don't know R=4E refer to? Do you mean 4Ohm?

Could you measure the SW waveform by a 500MHz or higher probe/oscilloscope to see if it produces these frequency's noise?

Another thing you can try is adding a 5Ohm resistor in series with C127.

Thanks.

Regards,

Shipeng

Hi Shipeng,

Yes 4E means 4 ohm resistor.

Could you measure the SW waveform by a 500MHz or higher probe/oscilloscope to see if it produces these frequency's noise? - Yes will try.

Another thing you can try is adding a 5Ohm resistor in series with C127 - How this will help?

Thanks,

Brijesh K

Hi Brijesh,

Adding the resistor can slow down the slew rate of SW voltage and reduce the spike.

Thanks,

Shipeng

Hi Shipeng,

Hi Shipeng,

Waiting for reply please as we do have to go RE LAB for testing so can u plz confirm above so can rework it and go for testing?

HI Brijesh,

Adding resistor can improve a little power loss, no other problems. RC snubber don't need to be changed.

Thanks.

Regards,

Shipeng

Hi Shipeng,

Thank you for suggestions and confirmation, will try this and let you know results.

Thank you,

Brijesh K

Hi Shipeng,

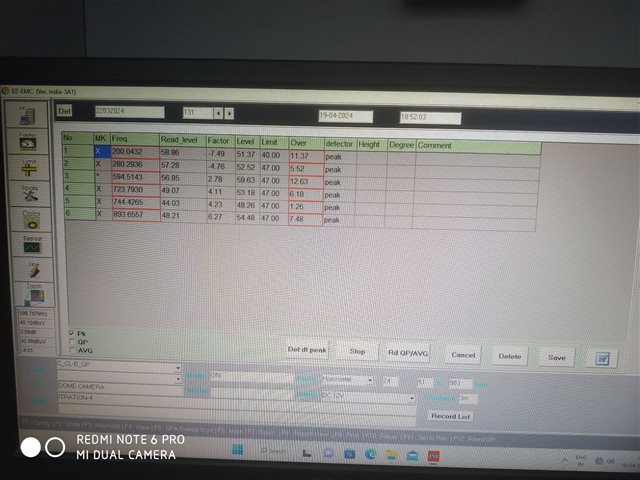

This are results with Adding Series resistor 5.76 ohm with C127, Snubber is R = 4 ohm & C = 0.2uF. Results seems not good. Please suggest better way.

Hi Shipeng,

Except 3.3V we do have other 2 regualtors as well in our design.

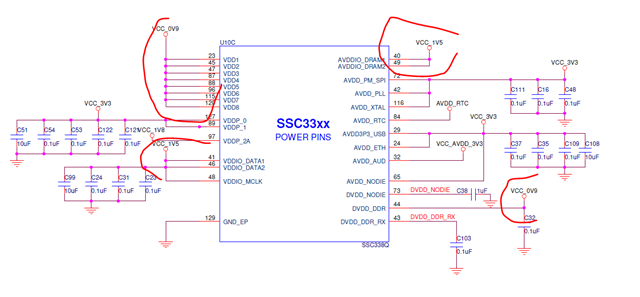

1) 0.9V regulator (SoC) Core supply - 700 mA and 2) 1.5V regulator - (SoC and Internal DRAM) - 250 mA

Do you think that these both also can be source of Radiations Because we have seen improvements by pacing RC snubber on 3.3V regulator so do you have any thoughts for these other 2 regulators?

Thanks,

Brijesh K

Hi Brijesh,

Yes, all swithing regulators can be source of EMI so you can add RC snubber circuit to them. You can also post a new e2e thread to get advice from TLV62568 engineers.

Thanks.

Regards,

Shipeng