Other Parts Discussed in Thread: EV2400, BQ28Z610

Hi everyone.

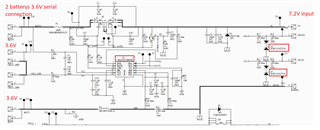

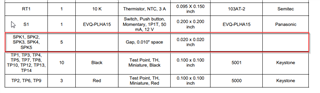

I have a design use BQ28Z610-R1 as attached file. I also use ESD5581N2T5G to protect I/O pin when I connect them with external peripheral device.

I have tested this PCBA FCT(Programming with EV2400), they are working without any problem, but when we apply weld process after that we test this PCBA FCT(Programming with EV2400) again we can not program or scan I2C address on my PCBA (ratio 5% in my production), that means I2C module of BQ28Z610-R1 have a problem after weld process. I replace the new BQ28Z610-R1-> this PCBA passed. I Use battery 7.2V and power supply for Pack pin is 7.2V.

I know that:

- ESD5581N2T5G have Voltage Reverse:5V, Voltage clamping 12V.

- BQ28Z610-R1: SDA, SCL Pin input maximum 5.5V as datasheet mentioned.

My concern:

- Whether when we apply weld process, it will generate ESD, this ESD can damage 2C module of BQ28Z610-R1. But I have ESD diode to protect this, so why this can happen?

- SDA, SCL Pin input maximum 5.5V as datasheet mentioned, we use ESD diode with Voltage Reverse:5V, Voltage clamping 12V. This diode can protect 2C module of BQ28Z610-R1 or not?

- If we change ESD5581N2T5G to an ESD diode with Voltage Reverse:3.3V whether we can improve this problem.

- Do you have any advice to improve my situation?