Other Parts Discussed in Thread: GPCRB, BQSTUDIO

Tool/software:

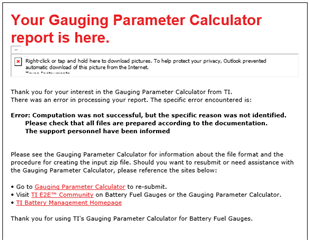

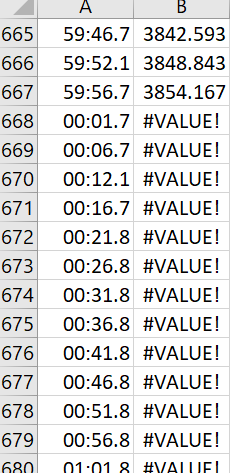

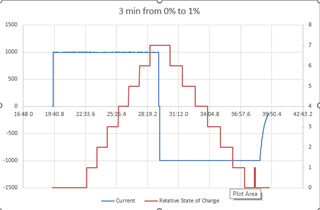

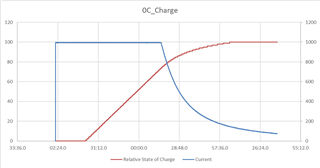

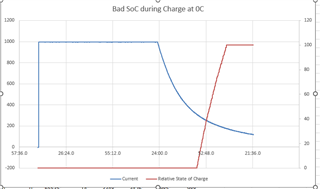

Last week, I performed the GPCRB procedure to optimize gauging at cold temperature. However, the gauge had done some learning with the learning cycle previously. I did the GPCRB procedure now knowing this was a problem, and got the error after I sent in the zip file:

The following errors were reported by the calculation engine:

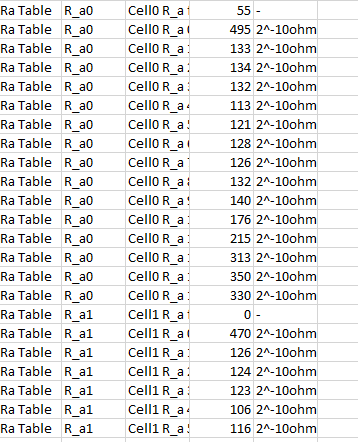

Error: Ra table could not be extracted from GG file. Make sure that chem ID was freshly programmed and no learning took place. Flags ff55 or ffff should be present 0

So this week I programmed the chem ID fresh, and I confirmed that the Ra table showed the flags = FF55 and FFFF before I began the procedure again. Then I sent in the data, but I'm getting the same error:

The following errors were reported by the calculation engine:

Error: Ra table could not be extracted from GG file. Make sure that chem ID was freshly programmed and no learning took place. Flags ff55 or ffff should be present 0

Why is this? The chem ID was already freshly programmed and the flags were FF55 FFFF before I started.

Thanks,

Kelvin