Other Parts Discussed in Thread: EV2400, , GPCCHEM

Tool/software:

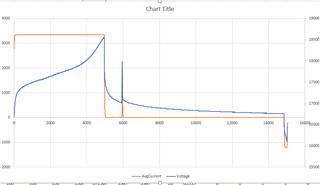

I am having difficulty completing the learning cycle on our board utilizing the BQ34Z100. I have the EV2400 programmer and have successfully calibrated the gauge and have tried multiple times to get the gauge calibrated. I have yet to see the learned status switch to 05 from 04. Attached are the latest charge log and export of settings. I'm guessing that my setting are not quite right yet.

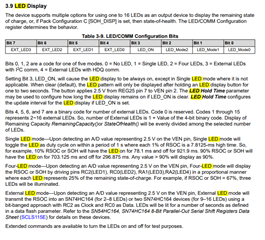

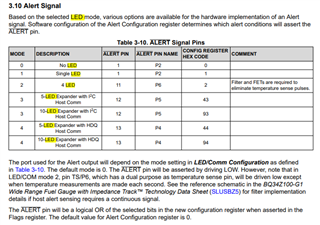

My other issue is getting the 4 LED configuration to work correctly. I have tried an external configuration as well as using the 4 LED built in configuration. I am using the I2C port and I think it makes sense that I cannot use the port and have the 4 LED built in configuration operational. But do I have to switch to HDQ mode to utilize the built in 4 LED?? Perhaps this is a mute topic until the gauge completes a learning cycle? I just assume that the LED should mimic the gauge as shown in BQ Studio if its 77% I expect 3 LED's lit if each LED represents 25%. I do not want to show SOH just RSOC.

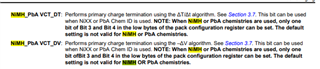

My Battery pack is 14.4V 4.5AH (64.8Wh) and consists of 12 1.2V NiMH batteries is series. I'm using NiMH CHEM ID of 0641 which was the closest match at I think 4%. What setting are needed for NiMH, I assume I can leave taper current empty or default and its not used being that a NiMH CHEM ID is being used? Looks like I need to run another discharge cycle one I ran last night did not save.

My program deadline is approaching and would like to get this gauge working to a point that instills a higher confidence level in moving forward with this design.